- Control Valve

- Pneumatic Control Valve

- Pneumatic Angle Control Valve

- 3 Way pneumatic Diaphragm Control Valve

- 3 Way Converging and Diverging Control Valve

- Fluorine Lined Single Seat Control Valve

- Pneumatic Cage Control Valve

- Pneumatic Double Seat Control Valve

- Pneumatic Single Seat Globe Control Valve

- Pneumatic Flow Control Valve

- Pneumatic Sleeve Type Control Valve

- Pneumatic Actuated Globe Type Control Valve

- Electric Actuated Control Valve

- Pneumatic Control Valve

- Cryogenic Valve

- Pressure Reducing Valve

- Safety Valve

- Check Valve

- Gate Valve

- Butterfly Valve

- Globe Valve

- Ball Valve

- Electric Actuated Valve

- Electric Actuated Ball Valve

- Electric Actuated Butterfly Valve

- Electric Actuated Gate Valve

- Electric Actuated Globe Valve

- Pneumatic Actuated Valve

- Plunger Valve

- Strainers

- Steam Trap

- Knife Gate Valve

- Speciality Valve

- Alloy 20 Valve

- Duplex Valve

- Super Duplex Valve

- Hastelloy C276/B3 Valve

- Aluminium Bronze Valve

- Titanium Valve

- Bronze Valve

- Monel Valve

- Triple Duty Valve

- Suction Diffuser

- Diaphragm Valve

- Plug Valve

- Foot Valve

- Air Release Valve

- Surge Anticipator Valve

- Needle Valve

- Balancing Valve

FLANGE

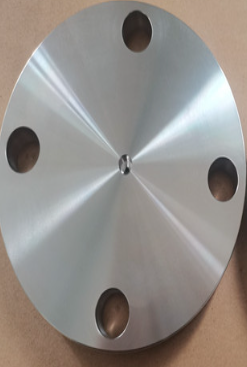

Middleeast valve is the foremost Flange manufacturers in UAE. A flange is a projecting flat rim, collar, or rib on an object, serving to strengthen or attach, or to maintain position on a rail. Commonly, it refers to a type of mechanical connector used in piping systems, valves, pumps, and other equipment where two sections need to be joined together, providing an effective seal and strength for pressure and flow.

Flanges are essential components in various industries, including oil and gas, chemical, petrochemical, power generation, and water treatment, where robust and reliable connections are crucial.

Working of Flanges

Flanges work by aligning and bolting together two separate sections of a piping system or a piece of equipment. The process involves the following steps:

- Preparation: The flange faces are cleaned and inspected for any damage or deformities. The gasket, which is a key element in creating a seal, is selected based on the application’s pressure and temperature requirements.

- Alignment: The flanges are aligned to ensure that the bolt holes match. Misalignment can lead to leakage or mechanical failure.

- Insertion of Gasket: A gasket is placed between the flange faces to provide a tight seal. The material of the gasket depends on the media being transported and the operating conditions.

- Bolting: Bolts are inserted into the flange holes and tightened in a specific sequence to ensure even distribution of pressure. The torque applied to the bolts is carefully controlled to avoid over-tightening, which can damage the flange or gasket, and under-tightening, which can result in leaks.

- Inspection: Once the flanges are bolted together, the assembly is inspected for alignment, bolt torque, and overall integrity to ensure a secure and leak-free connection.

Design Options: There are several flange designs, each suited to specific requirements:

- Weld Neck Flanges: Provide a robust connection with high pressure and temperature capability.

- Slip-On Flanges: Easier to install and align, suitable for lower pressure applications.

- Blind Flanges: Used to close the end of a piping system, allowing for future expansion or maintenance.

- Threaded Flanges: Can be assembled without welding, useful for small diameter, low-pressure systems.

- Socket Weld Flanges: Ideal for small-diameter, high-pressure pipelines.

Flange manufacturers in UAE are vital components in many industrial systems, providing strong, flexible, and reliable connections.

Description:

- Size:½” (15 NB) to 48″ (1200NB)

- Standard: ANSI B16.5, ANSI B16.47, ANSI B16.36, ANSI B16.48, BS 4504, EN1092, UNI 2277/2278, DIN, JIS, SABS1123, GOST-12820

- Dimensions: ANSI B16.5, ANSI B16.47 Series A & B, MSS SP44, ASA, API-605, AWWA

- Class: 150 LBS, 300 LBS, 600 LBS, 900 LBS, 1500 LBS, 2500 LBS, DIN Standard ND-6,10, 16, 25, 40.

- DIN : DIN2527, DIN2566, DIN2573, DIN2576, DIN2641, DIN2642, DIN2655, DIN2656, DIN2627, DIN2628, DIN2629, DIN 2631, DIN2632, DIN2633, DIN2634, DIN2635, DIN2636, DIN2637, DIN2638, DIN2673

- BS: BS4504 , BS4504, BS1560, BS10

- Flange Connection Type: Ring Type Joint, Lap-Joint Face, Raised Face, Flat Face.