- Control Valve

- Pneumatic Control Valve

- Pneumatic Angle Control Valve

- 3 Way pneumatic Diaphragm Control Valve

- 3 Way Converging and Diverging Control Valve

- Fluorine Lined Single Seat Control Valve

- Pneumatic Cage Control Valve

- Pneumatic Double Seat Control Valve

- Pneumatic Single Seat Globe Control Valve

- Pneumatic Flow Control Valve

- Pneumatic Sleeve Type Control Valve

- Pneumatic Actuated Globe Type Control Valve

- Electric Actuated Control Valve

- Pneumatic Control Valve

- Cryogenic Valve

- Pressure Reducing Valve

- Safety Valve

- Check Valve

- Gate Valve

- Butterfly Valve

- Globe Valve

- Ball Valve

- Electric Actuated Valve

- Electric Actuated Ball Valve

- Electric Actuated Butterfly Valve

- Electric Actuated Gate Valve

- Electric Actuated Globe Valve

- Pneumatic Actuated Valve

- Plunger Valve

- Strainers

- Steam Trap

- Knife Gate Valve

- Speciality Valve

- Alloy 20 Valve

- Duplex Valve

- Super Duplex Valve

- Hastelloy C276/B3 Valve

- Aluminium Bronze Valve

- Titanium Valve

- Bronze Valve

- Monel Valve

- Triple Duty Valve

- Suction Diffuser

- Diaphragm Valve

- Plug Valve

- Foot Valve

- Air Release Valve

- Surge Anticipator Valve

- Needle Valve

- Balancing Valve

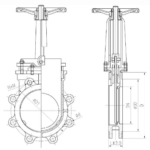

Flanged Knife Gate Valve Suppliers in Saudi Arabia: Efficient Flow Isolation

Middleeast valve is the leading Flanged knife gate valve suppliers in Saudi Arabia. It is a type of valve designed to handle thick fluids and slurries with high solids content. It is named for its sharp-edged gate that can cut through such materials, providing a clean and effective shut-off.

Major Components:

- Gate (Knife): Thin, vertically moving blade to obstruct or permit flow

- Body: Sturdy frame, typically constructed of stainless steel or cast iron

- Flanged Ends: Facilitate simple bolted connection to piping

- Seats: Provide tight seating against the gate

- Actuator: Manual, pneumatic, or electric according to system requirement

Working Mechanism:

While actuated, the gate rotates up or down between the seats within the valve body. For the closed mode, it fully shuts off the flow. Flanged ends form a leak-tight connection with the piping system, which renders it extremely safe under pressure.

Advantages:

- Easy installation and removal owing to flanged design

- Ideal for slurry and solid media handling

- Space-saving and compact structure

- Facilitates high-pressure and high-temperature applications

- Low maintenance and long service life

Industries Served:

- Mining & Slurry Handling

- Wastewater Treatment

- Pulp & Paper Industry

- Chemical & Petrochemical

Description:

Available materials: WCB, WC6, WCC, LCB, LCC, Cast iron, Ductile Iron, SS316, SS304

Size: 2″ to 80″

Class: 150 to 300

Nominal Pressure: PN6 to PN40

Operation: Handwheel, Electric and Pneumatic Actuated, Gear operated

Ends: Wafer, Lug, Flanged