- Control Valve

- Pneumatic Control Valve

- Pneumatic Angle Control Valve

- 3 Way pneumatic Diaphragm Control Valve

- 3 Way Converging and Diverging Control Valve

- Fluorine Lined Single Seat Control Valve

- Pneumatic Cage Control Valve

- Pneumatic Double Seat Control Valve

- Pneumatic Single Seat Globe Control Valve

- Pneumatic Flow Control Valve

- Pneumatic Sleeve Type Control Valve

- Pneumatic Actuated Globe Type Control Valve

- Electric Actuated Control Valve

- Pneumatic Control Valve

- Cryogenic Valve

- Pressure Reducing Valve

- Safety Valve

- Check Valve

- Gate Valve

- Butterfly Valve

- Globe Valve

- Ball Valve

- Electric Actuated Valve

- Electric Actuated Ball Valve

- Electric Actuated Butterfly Valve

- Electric Actuated Gate Valve

- Electric Actuated Globe Valve

- Pneumatic Actuated Valve

- Plunger Valve

- Strainers

- Steam Trap

- Knife Gate Valve

- Speciality Valve

- Alloy 20 Valve

- Duplex Valve

- Super Duplex Valve

- Hastelloy C276/B3 Valve

- Aluminium Bronze Valve

- Titanium Valve

- Bronze Valve

- Monel Valve

- Triple Duty Valve

- Suction Diffuser

- Diaphragm Valve

- Plug Valve

- Foot Valve

- Air Release Valve

- Surge Anticipator Valve

- Needle Valve

- Balancing Valve

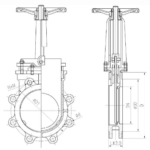

Flanged Knife Gate Valve

Middleeast valve is the leading Flanged knife gate valve suppliers in Saudi Arabia. A knife gate valve is a type of valve designed to handle thick fluids and slurries with high solids content. It is named for its sharp-edged gate that can cut through such materials, providing a clean and effective shut-off.

The primary function of a knife gate valve is to control the flow of fluids, particularly those with suspended solids. It is used to either stop or allow the flow of a medium through a pipeline. The valve operates by moving a gate (or blade) up and down perpendicular to the flow direction, which either blocks or allows passage of the material.

What is flanged knife gate valve?

A flanged knife gate valve is a variant of the knife gate valve that features flanged ends. These flanges allow the valve to be bolted directly to the pipeline, providing a secure and leak-proof connection. Flanged knife gate valves are commonly used in applications where a robust and easy-to-install connection is required.

The function of a flanged knife gate valve is similar to that of a standard knife gate valve: to control the flow of fluids, particularly those containing solids or viscous substances. The flanged ends provide added stability and ease of installation, making it suitable for heavy-duty applications.

Working Theory:

The working theory of a flanged knife gate valve is identical to that of the standard knife gate valve. The main difference lies in the connection method:

Flanged Connection: The flanges on the valve body are bolted to corresponding flanges on the pipeline. Gaskets are used between the flanges to ensure a tight seal.

Operation: The gate moves up and down between the flanges to control the flow of fluid. When the gate is raised, fluid flows freely; when it is lowered, the flow is stopped.

Features:

Secure Connection: The flanged ends provide a secure and leak-proof connection to the pipeline, reducing the risk of leaks and ensuring operational safety.

Robust Design: Flanged knife gate valves are designed to withstand high pressures and harsh conditions, making them suitable for industrial applications such as mining and wastewater treatment.

Ease of Installation: The flanged design simplifies the installation process, allowing for quick and straightforward mounting onto the pipeline.

Flanged knife gate valve suppliers in Saudi Arabia offers reliable and efficient solutions for controlling the flow of fluids with high solids content.

Description:

Available materials: WCB, WC6, WCC, LCB, LCC, Cast iron, Ductile Iron, SS316, SS304

Size: 2″ to 80″

Class: 150 to 300

Nominal Pressure: PN6 to PN40

Operation: Handwheel, Electric and Pneumatic Actuated, Gear operated

Ends: Wafer, Lug, Flanged