- Control Valve

- Pneumatic Control Valve

- Pneumatic Angle Control Valve

- 3 Way pneumatic Diaphragm Control Valve

- 3 Way Converging and Diverging Control Valve

- Fluorine Lined Single Seat Control Valve

- Pneumatic Cage Control Valve

- Pneumatic Double Seat Control Valve

- Pneumatic Single Seat Globe Control Valve

- Pneumatic Flow Control Valve

- Pneumatic Sleeve Type Control Valve

- Pneumatic Actuated Globe Type Control Valve

- Electric Actuated Control Valve

- Pneumatic Control Valve

- Cryogenic Valve

- Pressure Reducing Valve

- Safety Valve

- Check Valve

- Gate Valve

- Butterfly Valve

- Globe Valve

- Ball Valve

- Electric Actuated Valve

- Electric Actuated Ball Valve

- Electric Actuated Butterfly Valve

- Electric Actuated Gate Valve

- Electric Actuated Globe Valve

- Pneumatic Actuated Valve

- Plunger Valve

- Strainers

- Steam Trap

- Knife Gate Valve

- Speciality Valve

- Alloy 20 Valve

- Duplex Valve

- Super Duplex Valve

- Hastelloy C276/B3 Valve

- Aluminium Bronze Valve

- Titanium Valve

- Bronze Valve

- Monel Valve

- Triple Duty Valve

- Suction Diffuser

- Diaphragm Valve

- Plug Valve

- Foot Valve

- Air Release Valve

- Surge Anticipator Valve

- Needle Valve

- Balancing Valve

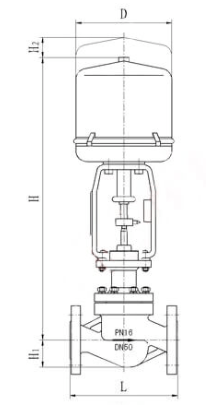

Electric Globe Control Valve

A globe control valve is a type of flow control valve that is designed to regulate the flow of fluid through a pipe. It consists of a cylindrical body with a spherical disc that acts as the controlling element. The disc is connected to a stem, which is connected to an actuator that moves the disc to open or close the valve. An electric globe control valve is a type of flow control valve that uses an electric actuator to control the movement of the valve’s stem and thereby regulate the flow of fluid through the valve. The valve is typically used in industrial and commercial applications to control the flow of fluids such as water, oil, gas, and steam. The electric actuator allows for precise and remote control of the valve, and the globe valve design allows for good throttling control. The valve can be controlled using various control systems such as PLC, DCS, and SCADA.

Parts

Valve body

Valve stem

Valve plug

Actuator

Positioner

Limit switches

Solenoid

Advantages

These valves can provide precise control of flow rate and pressure, making them suitable for applications that require tight control of process variables.

They can be easily integrated with control systems and automated, which allows for remote control and monitoring of the valve’s position.

They provide fast response times, which allows for quick adjustments to the valve’s position in response to changes in process conditions.

They have fewer moving parts than other types of valves, which results in less wear and tear and less maintenance.

These valves are safer to operate than manual valves because they can be controlled remotely and are less likely to be tampered with.

Electric globe control valves are cost-effective because they require less maintenance and can be easily integrated with control systems.

Industries which use them

Chemical and Petrochemical Industries

Power generation Plants

Oil and gas Industry

Pulp and Paper Industry

Water and Wastewater Treatment

Application

Electric globe control valves are used to control the flow of fluids in pipelines, such as controlling the flow of water in a water treatment plant or the flow of steam in a power generation plant.

These valves are used to control the pressure of fluids in a process, such as maintaining a constant pressure in a chemical processing plant.

These valves are used to control the temperature of fluids in a process, such as controlling the temperature of water in a heating system or the temperature of a fluid in a reactor.

They are used to control the level of fluids in a tank or vessel, such as maintaining a constant level of liquid in a storage tank.

They are used to turn the flow of fluid on and off, such as in pipeline shut-off valves or emergency shut-off valves.

It is used to control the flow rate of fluids, such as in flow metering applications.

Combustion control: Electric globe control valves are used to control the flow of fuel and air in combustion systems, such as in boilers or furnaces.

Safety systems: Electric globe control valves are also used in safety systems to shut off the flow of fluid in case of emergency, such as in overpressure protection systems.