- Control Valve

- Pneumatic Control Valve

- Pneumatic Angle Control Valve

- 3 Way pneumatic Diaphragm Control Valve

- 3 Way Converging and Diverging Control Valve

- Fluorine Lined Single Seat Control Valve

- Pneumatic Cage Control Valve

- Pneumatic Double Seat Control Valve

- Pneumatic Single Seat Globe Control Valve

- Pneumatic Flow Control Valve

- Pneumatic Sleeve Type Control Valve

- Pneumatic Actuated Globe Type Control Valve

- Electric Actuated Control Valve

- Pneumatic Control Valve

- Cryogenic Valve

- Pressure Reducing Valve

- Safety Valve

- Check Valve

- Gate Valve

- Butterfly Valve

- Globe Valve

- Ball Valve

- Electric Actuated Valve

- Electric Actuated Ball Valve

- Electric Actuated Butterfly Valve

- Electric Actuated Gate Valve

- Electric Actuated Globe Valve

- Pneumatic Actuated Valve

- Plunger Valve

- Strainers

- Steam Trap

- Knife Gate Valve

- Speciality Valve

- Alloy 20 Valve

- Duplex Valve

- Super Duplex Valve

- Hastelloy C276/B3 Valve

- Aluminium Bronze Valve

- Titanium Valve

- Bronze Valve

- Monel Valve

- Triple Duty Valve

- Suction Diffuser Valve

- Diaphragm Valve

- Plug Valve

- Foot Valve

- Air Release Valve

- Surge Anticipator Valve

- Needle Valve

- Balancing Valve

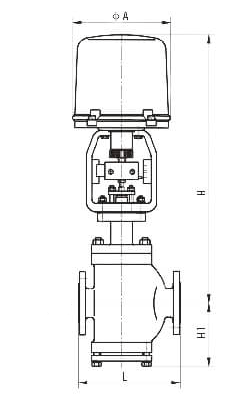

Electric double seat control valve

Middleeast is a leading and famous double-seat control valve supplier in Qatar. An electric double seat control valve is a type of control valve that uses two seats, or sealing surfaces, to control the flow of a fluid. The valve is controlled by an electric actuator, which uses an electric motor to move the valve stem and change the position of the valve. An actuator in an electric double seat control valve is the component that converts electrical energy into mechanical motion to open or close the valve. The actuator is typically powered by an electric motor that is controlled by a control unit. The two seats in the valve can be used to control the flow of the fluid in different ways, such as by adjusting the flow rate or by shutting off the flow entirely. Electric double seat control valves are often used in industrial process control applications, such as in oil and gas or chemical processing plants.

Middleeast is the largest electric double-seat control valve supplier in Qatar. While manufacturing, we keep in mind the industrial standards and maintain the quality standards of the valves.

Parts

Valve Body

Actuator

Control Uni

Seats

Stem

Packing

Limit Switches

Solenoid

Air filter

Positioner

Advantages

These valves have the ability to independently control the flow through each seat of the valve allows for precise flow control, which can be useful in applications where fine-tuning of the flow rate is required.

Electric double seat control valves can be controlled remotely using electronic control systems, which allows for easy and convenient operation from a remote location.

They are highly repeatable, meaning that the valve can be opened or closed to the same position each time with minimal variation. This can be useful in applications where consistent flow is required.

They can respond quickly to control signals, allowing for fast and accurate control of the flow rate.

They are relatively low maintenance, compared to other types of actuators, as they do not require regular lubrication or adjustment.

These valves are not affected by corrosive or explosive environments, which makes it a good option for those kind of applications.

Electric double seat control valves can be cost-effective in the long run, since they require less maintenance, and the cost of electricity is usually lower than the cost of compressed air or other types of actuation.

These valves can be equipped with safety features such as limit switches and positioners that ensure that the valve is in the correct position and prevents overtravel.

Industries which use them

Oil and Gas Industry

Chemical Industry

Power Generation Plants

Pulp and Paper Industry

Water Treatment Plants

Applications

These valves are used to control the flow of liquids, gases, and steam in industrial processes.

They are used to control the pressure of fluids in industrial processes.

Electric double seat control valves are used to control the temperature of fluids in industrial processes.

They are used to control the flow of fluids in mixing and blending processes.

These valves are used to control the flow rate of fluids in industrial processes, this is particularly useful in applications where fine-tuning of the flow rate is required.

These control valves are used in On/Off control applications, where the valve is fully open or fully closed.

They are used in Proportional control applications, where the valve is open or closed gradually to allow a precise flow control.

Are used in automatic control applications, where the valve is controlled by a process control system.

These are used in safety and emergency shut-off systems, where the valve can be quickly closed to stop the flow of fluid in case of an emergency.

Electric double seat control valves are used in bypass systems, where the valve is used to redirect the flow of fluid around a piece of equipment or a process.