- Control Valve

- Pneumatic Control Valve

- Pneumatic Angle Control Valve

- 3 Way pneumatic Diaphragm Control Valve

- 3 Way Converging and Diverging Control Valve

- Fluorine Lined Single Seat Control Valve

- Pneumatic Cage Control Valve

- Pneumatic Double Seat Control Valve

- Pneumatic Single Seat Globe Control Valve

- Pneumatic Flow Control Valve

- Pneumatic Sleeve Type Control Valve

- Pneumatic Actuated Globe Type Control Valve

- Electric Actuated Control Valve

- Pneumatic Control Valve

- Cryogenic Valve

- Pressure Reducing Valve

- Safety Valve

- Check Valve

- Gate Valve

- Butterfly Valve

- Globe Valve

- Ball Valve

- Electric Actuated Valve

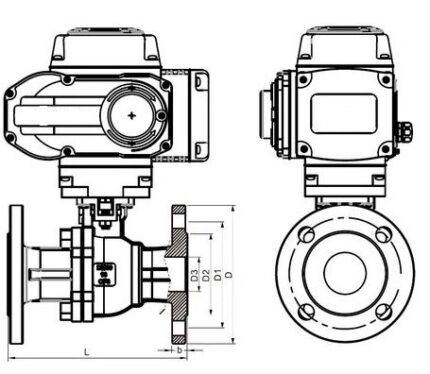

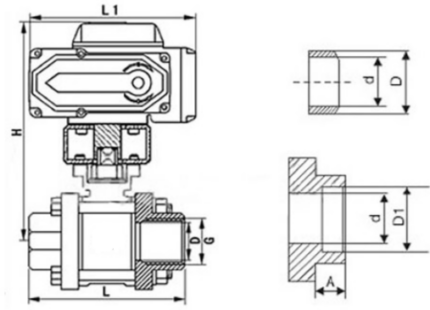

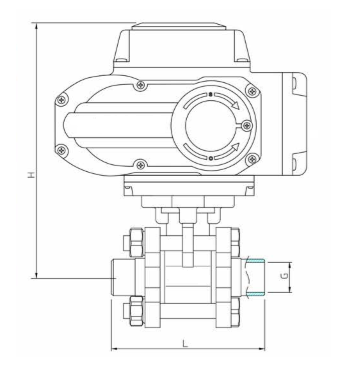

- Electric Actuated Ball Valve

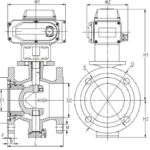

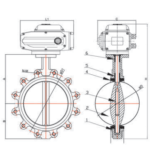

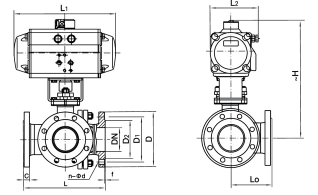

- Electric Actuated Butterfly Valve

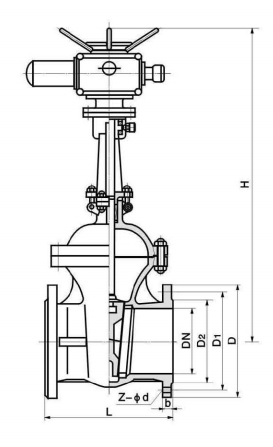

- Electric Actuated Gate Valve

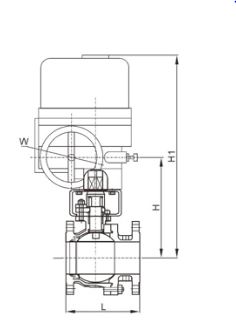

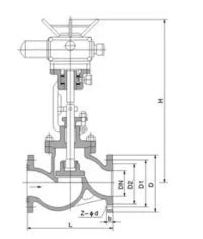

- Electric Actuated Globe Valve

- Pneumatic Actuated Valve

- Plunger Valve

- Strainers

- Steam Trap

- Knife Gate Valve

- Speciality Valve

- Alloy 20 Valve

- Duplex Valve

- Super Duplex Valve

- Hastelloy C276/B3 Valve

- Aluminium Bronze Valve

- Titanium Valve

- Bronze Valve

- Monel Valve

- Triple Duty Valve

- Suction Diffuser

- Diaphragm Valve

- Plug Valve

- Foot Valve

- Air Release Valve

- Surge Anticipator Valve

- Needle Valve

- Balancing Valve

Electric Actuated Valve Suppliers in UAE: Smart Flow Control for Modern Systems

Middleeast valve is the topmost Electric Actuated Valve Suppliers in UAE. It is a device used to control the flow of fluids (liquids or gases) through a pipeline or process system by means of an electric motor or actuator. These valves are commonly used in industrial and commercial applications to automate and control various processes, such as fluid handling, heating, cooling, and more.

Key Components of Electric Actuated Valve:

1)Valve Body: It is housing the flow control mechanism.

2)Electric Actuator: Electric energy is converted to mechanical motion

3)Stem and Disc/Ball/Gate: Regulate the flow through the valve.

4)Control Unit: Regulates the feedback and functioning of the actuator

Working of Electric Actuated Valve:

A control system sends signals to electric actuated valves, which then act. When required, the actuator opens, closes, or throttles flow by rotating or raising the valve element (ball, gate, or disc). With automation capabilities and position feedback, they give precise control.

Advantages of Electric Actuated Valve:

1)Automated and remote control

2)Precise regulation of pressure and flow

3)Low maintenance and energy-efficient

4)Ideal for hazardous or hard-to-reach areas

Types:

1)Electric ball Actuated Valve

2)Electric butterfly Actuated valve

3)Electric globe Actuated valve

4)Electric Gate Actuated Valve

Industries:

1)Mining

2)Chemical

3)Power Industries

4)Boilers Industries

Description:

Available Materials: CF8M, CF8, SS316, CF3M, WCB, and Stainless steel (SS304, SS316, CF8M, SS316L, SS904L).

Class: 150 to 2500

Size: 1/2″ to 80″

End Connections: Flanged, Socket weld, Butt weld, Threaded, Wafer, Lug

Operation: Electric Actuator.

Electric actuator details-

1)Torque – 3 – 9 nm

2)Operating pressure- 8 Bar

3)Port Connection-NPT1.4”

4)Mounting Base-ISO5211

5)Temperature–20°C – +80°C

6)Body material-Aluminium