- Control Valve

- Pneumatic Control Valve

- Pneumatic Angle Control Valve

- 3 Way pneumatic Diaphragm Control Valve

- 3 Way Converging and Diverging Control Valve

- Fluorine Lined Single Seat Control Valve

- Pneumatic Cage Control Valve

- Pneumatic Double Seat Control Valve

- Pneumatic Single Seat Globe Control Valve

- Pneumatic Flow Control Valve

- Pneumatic Sleeve Type Control Valve

- Pneumatic Actuated Globe Type Control Valve

- Electric Actuated Control Valve

- Pneumatic Control Valve

- Cryogenic Valve

- Pressure Reducing Valve

- Safety Valve

- Check Valve

- Gate Valve

- Butterfly Valve

- Globe Valve

- Ball Valve

- Electric Actuated Valve

- Electric Actuated Ball Valve

- Electric Actuated Butterfly Valve

- Electric Actuated Gate Valve

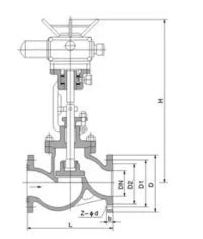

- Electric Actuated Globe Valve

- Pneumatic Actuated Valve

- Plunger Valve

- Strainers

- Steam Trap

- Knife Gate Valve

- Speciality Valve

- Alloy 20 Valve

- Duplex Valve

- Super Duplex Valve

- Hastelloy C276/B3 Valve

- Aluminium Bronze Valve

- Titanium Valve

- Bronze Valve

- Monel Valve

- Triple Duty Valve

- Suction Diffuser

- Diaphragm Valve

- Plug Valve

- Foot Valve

- Air Release Valve

- Surge Anticipator Valve

- Needle Valve

- Balancing Valve

An Electric Actuated Globe Valve is a type of valve that combines a traditional globe valve’s flow control capabilities with an electric actuator. This integration allows for remote operation and precise flow regulation in various applications, making it ideal for processes requiring automation and control.

The working mechanism of an Electric Actuated Globe Valve involves several components:

1)Globe Valve Body: The valve body features a spherical shape with an internal baffle that directs the flow of fluid. The flow path is typically linear, allowing for efficient throttling and regulation.

2)Electric Actuator: The actuator is powered by electricity and converts electrical energy into mechanical motion. It typically uses a motor that drives a screw mechanism, which raises or lowers the valve stem.

3)Positioning: The actuator is equipped with feedback systems such as limit switches and position sensors. These components allow for precise positioning of the valve stem, ensuring accurate flow control based on system requirements.

4)Control System: The electric actuator is often connected to a control system (such as a PLC or DCS), enabling remote monitoring and control. Operators can adjust the valve’s position through control commands, allowing for automated process adjustments.

Electric Actuated Globe Valves serve several essential functions in industrial applications:

1)Flow Regulation: They control the flow of liquids or gases through pipelines, allowing operators to adjust flow rates as needed.

2)Isolation: When fully closed, the valve can isolate sections of a system, preventing fluid movement and enabling maintenance.

3)Remote Operation: The electric actuator allows for remote operation, which enhances safety and convenience, particularly in hazardous environments.

4)Automation: Integration with control systems enables automated adjustments based on real-time data, enhancing process efficiency.

Electric Actuated Globe Valves come with a variety of features that enhance their performance:

1)High Precision: The electric actuator provides precise control over valve positioning, ensuring accurate flow regulation.

2)Energy Efficiency: These valves require less energy to operate compared to pneumatic or hydraulic actuators, leading to lower operational costs.

3)Durability: Constructed from robust materials, Electric Actuated Globe Valves are designed to withstand harsh environments and corrosive fluids.

4)Quick Response Time: The electric actuator allows for rapid opening and closing of the valve, enabling swift adjustments to flow rates.

5)Low Maintenance: With fewer moving parts than traditional valves, these valves often require less maintenance, reducing downtime.

Electric Actuated Globe Valves are vital components in modern industrial processes, providing reliable flow control and enhancing automation. Their integration of electric actuators with globe valve technology enables precise operation, making them suitable for a wide range of applications across various industries.