- Control Valve

- Pneumatic Control Valve

- Pneumatic Angle Control Valve

- 3 Way pneumatic Diaphragm Control Valve

- 3 Way Converging and Diverging Control Valve

- Fluorine Lined Single Seat Control Valve

- Pneumatic Cage Control Valve

- Pneumatic Double Seat Control Valve

- Pneumatic Single Seat Globe Control Valve

- Pneumatic Flow Control Valve

- Pneumatic Sleeve Type Control Valve

- Pneumatic Actuated Globe Type Control Valve

- Electric Actuated Control Valve

- Pneumatic Control Valve

- Cryogenic Valve

- Pressure Reducing Valve

- Safety Valve

- Check Valve

- Gate Valve

- Butterfly Valve

- Globe Valve

- Ball Valve

- Electric Actuated Valve

- Electric Actuated Ball Valve

- Electric Actuated Butterfly Valve

- Electric Actuated Gate Valve

- Electric Actuated Globe Valve

- Pneumatic Actuated Valve

- Plunger Valve

- Strainers

- Steam Trap

- Knife Gate Valve

- Speciality Valve

- Alloy 20 Valve

- Duplex Valve

- Super Duplex Valve

- Hastelloy C276/B3 Valve

- Aluminium Bronze Valve

- Titanium Valve

- Bronze Valve

- Monel Valve

- Triple Duty Valve

- Suction Diffuser

- Diaphragm Valve

- Plug Valve

- Foot Valve

- Air Release Valve

- Surge Anticipator Valve

- Needle Valve

- Balancing Valve

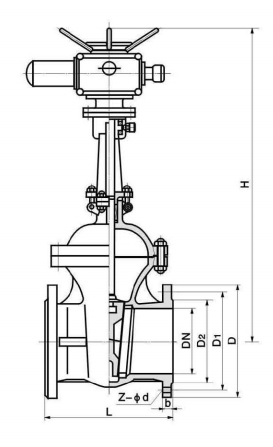

Electric Actuated Gate Valve

MiddleEast Valve is a well known Electric Actuated Gate valve in Iraq. Electric Actuators are a feature of this type of industrial valves, which automate valve action. The gate, a flat or wedge-shaped barrier that may be raised or lowered inside the valve body to regulate fluid flow, is the valve’s fundamental structural element. In an electric actuated gate valve, the electric actuator is a crucial part that offers automation. The valve is opened or shut using an electric motor or other electrical devices. Remote control of the actuator is frequently possible.

As these valves are powered by electricity they are renowned for being dependable and having quick responses. In reaction to commands, they can quickly open or close, lowering the possibility of manual errors and allowing quick changes in fluid flow. Because of their strength and durability, they can be used in high-pressure and high-temperature situations, providing dependable performance even under difficult circumstances.

Advantages:

Precise Control

Remote Operation

Reduced Labor Costs:

Consistency

Quick Response

Long Service Life

Industries and Applications:

Oil and Gas

Water and Wastewater Treatment

Chemical Processing

Power Generation

Pulp and Paper

Mining

Marine and Shipbuilding

Description:

Body Material: Cast Iron, Ductile Iron, 316L, SS304, SS316,CF8M, SS316L, SS904L,Wcb, Wcc, wc9, wc6

Size: DN15 to DN700

Pressure: PN10 to PN450,150 to 900

Ends: Flanged, Socket weld, Butt weld.

Operation: Electric actuated.

Electric actuator details–

Torque – 3 – 9 nm

Operating pressure- 8 Bar

Port Connection-NPT1.4”

Mounting Base-ISO5211

Temperature–20°C – +80°C