- Control Valve

- Pneumatic Control Valve

- Pneumatic Angle Control Valve

- 3 Way pneumatic Diaphragm Control Valve

- 3 Way Converging and Diverging Control Valve

- Fluorine Lined Single Seat Control Valve

- Pneumatic Cage Control Valve

- Pneumatic Double Seat Control Valve

- Pneumatic Single Seat Globe Control Valve

- Pneumatic Flow Control Valve

- Pneumatic Sleeve Type Control Valve

- Pneumatic Actuated Globe Type Control Valve

- Electric Actuated Control Valve

- Pneumatic Control Valve

- Cryogenic Valve

- Pressure Reducing Valve

- Safety Valve

- Check Valve

- Gate Valve

- Butterfly Valve

- Globe Valve

- Ball Valve

- Electric Actuated Valve

- Electric Actuated Ball Valve

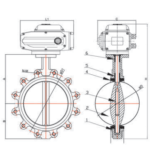

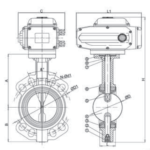

- Electric Actuated Butterfly Valve

- Electric Actuated Gate Valve

- Electric Actuated Globe Valve

- Pneumatic Actuated Valve

- Plunger Valve

- Strainers

- Steam Trap

- Knife Gate Valve

- Speciality Valve

- Alloy 20 Valve

- Duplex Valve

- Super Duplex Valve

- Hastelloy C276/B3 Valve

- Aluminium Bronze Valve

- Titanium Valve

- Bronze Valve

- Monel Valve

- Triple Duty Valve

- Suction Diffuser

- Diaphragm Valve

- Plug Valve

- Foot Valve

- Air Release Valve

- Surge Anticipator Valve

- Needle Valve

- Balancing Valve

Middleeast valve is the leading Electric actuated butterfly valve supplier in Saudi Arabia. An electric actuated butterfly valve is a type of valve used to control the flow of liquids and gases in various industrial applications. It combines a standard butterfly valve with an electric actuator, allowing for precise and automated control of the valve’s position. This integration enhances efficiency and provides remote operation capabilities.

The working principle of an electric actuated butterfly valve involves the following steps:

1)Electric Signal: An electrical signal is sent to the actuator, which is mounted on the butterfly valve.

2)Actuation: The electric actuator receives the signal and converts the electrical energy into mechanical motion.

3)Valve Operation: The mechanical motion turns the valve disc, which is positioned within the pipe. This turning motion can either block or allow fluid flow.

4)Position Control: The position of the valve disc can be precisely controlled, enabling accurate regulation of flow rates.

5)Feedback: Many systems provide feedback to ensure the valve reaches the desired position, enhancing reliability and control.

Features:

1)Automation: Electric actuators enable automated control, reducing the need for manual intervention.

2)Precision: Provides precise control over flow rates, essential for critical applications.

3)Remote Operation: Can be operated remotely, increasing convenience and safety.

4)Quick Response: Fast actuation speeds, suitable for applications requiring rapid response times.

5)Compatibility: Available in various sizes and materials to suit different fluids and operating conditions.

6)Durability: Designed to withstand harsh industrial environments.

Benefits

1)Increased Efficiency: Automation reduces human error and improves process efficiency.

2)Cost Savings: Lowers operational costs by minimizing manual labor and reducing the likelihood of errors.

3)Enhanced Safety: Remote operation and precise control enhance safety in hazardous environments.

4)Energy Savings: Efficient operation and reduced friction losses contribute to energy savings.

Electric actuated butterfly valve supplier in Saudi Arabia offer significant advantages in terms of automation, precision, and reliability, making them an essential component in modern industrial systems.

Description:

Material: Ductile Iron, Cast Iron, Duplex steel, 316L, SS304, SS316, CF8M, SS316L, SS904L, WCB, WCC, WC9, WC6

Class: 150 to 300 PN6 to PN25,

Size: 2” to 72”

Ends: Wafer, Lug, Flanged.

Operation- Electric actuated

Electric actuator details:

·Torque – 3 – 9 nm

·Operating pressure- 8 Bar

· Port Connection-NPT1.4”

· Mounting Base-ISO5211

·Temperature–20°C – +80°C