- Control Valve

- Pneumatic Control Valve

- Pneumatic Angle Control Valve

- 3 Way pneumatic Diaphragm Control Valve

- 3 Way Converging and Diverging Control Valve

- Fluorine Lined Single Seat Control Valve

- Pneumatic Cage Control Valve

- Pneumatic Double Seat Control Valve

- Pneumatic Single Seat Globe Control Valve

- Pneumatic Flow Control Valve

- Pneumatic Sleeve Type Control Valve

- Pneumatic Actuated Globe Type Control Valve

- Electric Actuated Control Valve

- Pneumatic Control Valve

- Cryogenic Valve

- Pressure Reducing Valve

- Safety Valve

- Check Valve

- Gate Valve

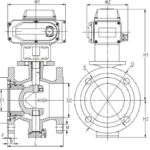

- Butterfly Valve

- Globe Valve

- Ball Valve

- Electric Actuated Valve

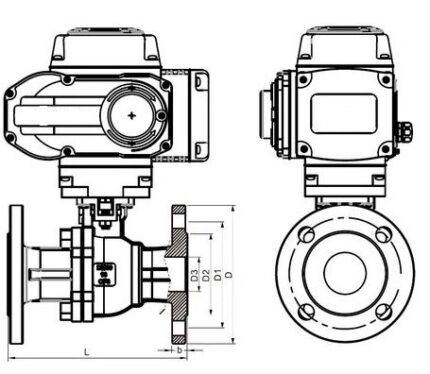

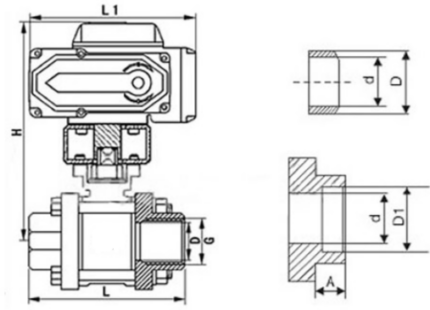

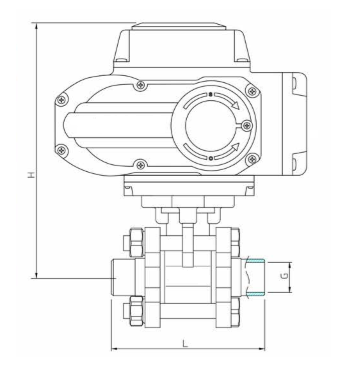

- Electric Actuated Ball Valve

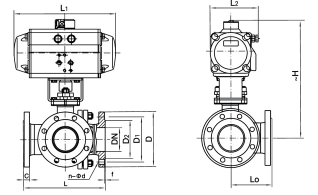

- Electric Actuated Butterfly Valve

- Electric Actuated Gate Valve

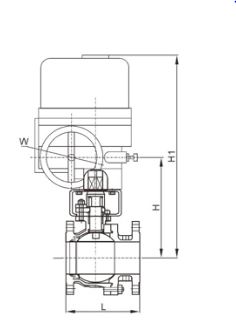

- Electric Actuated Globe Valve

- Pneumatic Actuated Valve

- Plunger Valve

- Strainers

- Steam Trap

- Knife Gate Valve

- Speciality Valve

- Alloy 20 Valve

- Duplex Valve

- Super Duplex Valve

- Hastelloy C276/B3 Valve

- Aluminium Bronze Valve

- Titanium Valve

- Bronze Valve

- Monel Valve

- Triple Duty Valve

- Suction Diffuser

- Diaphragm Valve

- Plug Valve

- Foot Valve

- Air Release Valve

- Surge Anticipator Valve

- Needle Valve

- Balancing Valve

An Electric Actuated Ball Valve is a type of valve that utilizes an electric actuator to open or close the valve, allowing for precise control of fluid flow within a piping system. This valve combines the reliability of a ball valve with the convenience of electric automation, making it suitable for various applications in industrial, commercial, and residential settings.

The working mechanism of an electric actuated ball valve involves several key components:

1)Valve Body: The valve consists of a hollow sphere (the ball) with a bore that allows fluid to pass through. When the ball is aligned with the flow, the valve is open; when rotated 90 degrees, the flow is stopped.

2)Electric Actuator: The electric actuator is the driving force behind the valve’s operation. It converts electrical energy into mechanical motion. When the actuator receives a signal (typically from a control system), it rotates the ball inside the valve to either open or close it.

3)Control System: The actuator is often connected to a control system that monitors and regulates the flow based on specific criteria, such as pressure, temperature, or flow rate. This allows for automated control, reducing the need for manual intervention.

4)Process of Operation:

Open Position: When the actuator receives an electrical signal to open the valve, it rotates the ball so that the bore aligns with the flow, allowing fluid to pass through.

Closed Position: Conversely, when the signal is to close the valve, the actuator rotates the ball 90 degrees to obstruct the flow completely.

The primary function of electric actuated ball valves includes:

1)Flow Control: They regulate the flow of liquids or gases in various systems, ensuring optimal operation.

2)Isolation: These valves provide reliable shut-off capabilities, isolating sections of a system for maintenance or safety purposes.

3)Automation: By integrating with control systems, they enable automated processes, enhancing efficiency and reducing the risk of human error.

4)Safety: In critical applications, electric actuated ball valves can quickly shut off flow in emergencies, preventing accidents and equipment damage.

Electric actuated ball valves come with several features that enhance their performance and usability:

1)Precision Control: The electric actuator allows for precise positioning, enabling accurate flow regulation.

2)Remote Operation: They can be operated remotely, which is ideal for hard-to-reach or hazardous locations.

3)Fast Response Time: Electric actuators can respond quickly to signals, making these valves suitable for applications requiring rapid adjustments.

4)Fail-Safe Options: Many electric actuated ball valves are designed with fail-safe mechanisms, ensuring that the valve defaults to a safe position during power outages or system failures.

5)Durability: Constructed from high-quality materials, these valves are designed to withstand harsh environments, making them suitable for various industries, including oil and gas, water treatment, and HVAC systems.

6)Energy Efficiency: Electric actuated ball valves often consume less energy compared to pneumatic or hydraulic systems, making them more environmentally friendly.

Electric actuated ball valves are essential components in modern fluid control systems, offering efficiency, safety, and reliability. Their ability to integrate with automation systems and provide precise flow control makes them invaluable in numerous industrial and commercial applications. Understanding their meaning, working, functions, and features can help industries leverage their advantages effectively.