- Control Valve

- Pneumatic Control Valve

- Pneumatic Angle Control Valve

- 3 Way pneumatic Diaphragm Control Valve

- 3 Way Converging and Diverging Control Valve

- Fluorine Lined Single Seat Control Valve

- Pneumatic Cage Control Valve

- Pneumatic Double Seat Control Valve

- Pneumatic Single Seat Globe Control Valve

- Pneumatic Flow Control Valve

- Pneumatic Sleeve Type Control Valve

- Pneumatic Actuated Globe Type Control Valve

- Electric Actuated Control Valve

- Pneumatic Control Valve

- Cryogenic Valve

- Pressure Reducing Valve

- Safety Valve

- Check Valve

- Gate Valve

- Butterfly Valve

- Globe Valve

- Ball Valve

- Electric Actuated Valve

- Electric Actuated Ball Valve

- Electric Actuated Butterfly Valve

- Electric Actuated Gate Valve

- Electric Actuated Globe Valve

- Pneumatic Actuated Valve

- Plunger Valve

- Strainers

- Steam Trap

- Knife Gate Valve

- Speciality Valve

- Alloy 20 Valve

- Duplex Valve

- Super Duplex Valve

- Hastelloy C276/B3 Valve

- Aluminium Bronze Valve

- Titanium Valve

- Bronze Valve

- Monel Valve

- Triple Duty Valve

- Suction Diffuser

- Diaphragm Valve

- Plug Valve

- Foot Valve

- Air Release Valve

- Surge Anticipator Valve

- Needle Valve

- Balancing Valve

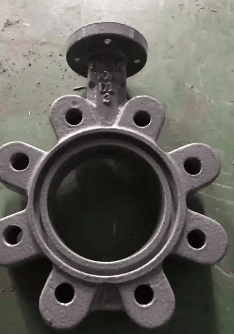

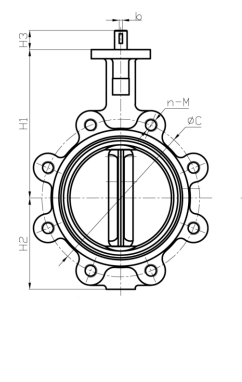

A Duplex Lug Butterfly Valve is a specialized type of butterfly valve designed with a “lug” mounting style and constructed from duplex stainless steel. The term “duplex” refers to a specific type of stainless steel that combines two phases—ferritic and austenitic—to achieve a balance of strength, toughness, and corrosion resistance. The “lug” design refers to the valve’s mounting configuration, where lugs or threaded inserts are integrated into the valve body, allowing for secure bolting to the pipeline.

Function

The primary function of the Duplex Lug Butterfly Valve is to control the flow of fluids—liquids or gases—through a pipeline. It achieves this by using a disc that rotates around its central axis. The position of the disc regulates the flow rate and pressure within the pipeline. The lug design allows the valve to be installed and removed without disturbing the pipeline system, which is particularly useful for maintenance and replacement.

Working:

Flow Control: Inside the valve, there is a disc mounted on a spindle that rotates to open or close the valve. When the valve is fully closed, the disc is perpendicular to the flow path, blocking the fluid. When the valve is open, the disc rotates parallel to the flow, allowing the fluid to pass through.

Actuation: The disc’s rotation is controlled by an actuator, which can be manual (like a handwheel or gear) or automated (such as an electric or pneumatic actuator). The actuator adjusts the disc’s position, allowing precise control over the fluid flow and pressure.

Sealing: The lug design of the valve body features threaded or bolted lugs that enable secure attachment to the pipeline flanges. This design minimizes the need for additional flanges or gaskets, simplifying installation and maintenance. The sealing is achieved through gaskets or O-rings that provide a tight seal to prevent leakage.

Installation: The lug design allows the valve to be sandwiched between two flanges with bolts inserted into the lugs. This mounting style makes it easier to install and remove the valve without affecting the rest of the pipeline, which is beneficial for maintenance or replacement.

Features:

Material – Duplex Stainless Steel: Duplex stainless steel offers a superior combination of strength, toughness, and corrosion resistance compared to standard stainless steels. Its dual-phase microstructure enhances its resistance to stress corrosion cracking and improves overall durability, making it suitable for demanding environments.

Lug Design: The lug mounting style allows for easy installation and removal. The lugs provide a secure bolting interface, which simplifies the process of attaching or detaching the valve from the pipeline.

Corrosion Resistance: Duplex stainless steel is highly resistant to corrosion, including pitting and crevice corrosion. This makes the valve suitable for use in aggressive environments, such as those involving chemicals or seawater.

High Strength: The duplex structure of the stainless steel provides greater strength and durability compared to other materials. This makes the valve suitable for high-pressure and high-temperature applications.

Compact Design: The lug butterfly valve is generally more compact and lighter than other valve types, which is beneficial for installations in space-constrained environments.

Ease of Maintenance: The lug design allows for straightforward maintenance and replacement. The valve can be removed and reinstalled without disturbing the adjacent pipeline components, reducing downtime and maintenance costs.

The Duplex Lug Butterfly Valve is a robust and versatile valve designed for precise flow control in challenging environments. Its duplex stainless steel construction ensures excellent strength and corrosion resistance, while the lug mounting style facilitates easy installation and maintenance. This combination of features makes it an ideal choice for a range of industrial applications.