- Control Valve

- Pneumatic Control Valve

- Pneumatic Angle Control Valve

- 3 Way pneumatic Diaphragm Control Valve

- 3 Way Converging and Diverging Control Valve

- Fluorine Lined Single Seat Control Valve

- Pneumatic Cage Control Valve

- Pneumatic Double Seat Control Valve

- Pneumatic Single Seat Globe Control Valve

- Pneumatic Flow Control Valve

- Pneumatic Sleeve Type Control Valve

- Pneumatic Actuated Globe Type Control Valve

- Electric Actuated Control Valve

- Pneumatic Control Valve

- Cryogenic Valve

- Pressure Reducing Valve

- Safety Valve

- Check Valve

- Gate Valve

- Butterfly Valve

- Globe Valve

- Ball Valve

- Electric Actuated Valve

- Electric Actuated Ball Valve

- Electric Actuated Butterfly Valve

- Electric Actuated Gate Valve

- Electric Actuated Globe Valve

- Pneumatic Actuated Valve

- Plunger Valve

- Strainers

- Steam Trap

- Knife Gate Valve

- Speciality Valve

- Alloy 20 Valve

- Duplex Valve

- Super Duplex Valve

- Hastelloy C276/B3 Valve

- Aluminium Bronze Valve

- Titanium Valve

- Bronze Valve

- Monel Valve

- Triple Duty Valve

- Suction Diffuser

- Diaphragm Valve

- Plug Valve

- Foot Valve

- Air Release Valve

- Surge Anticipator Valve

- Needle Valve

- Balancing Valve

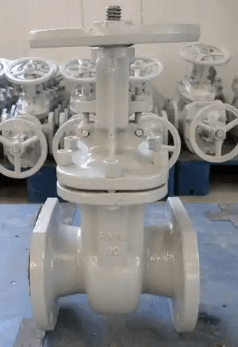

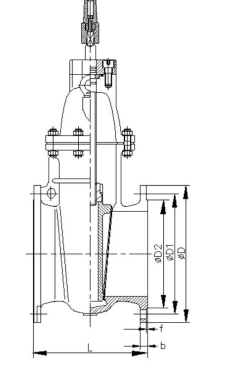

Middleeast Valve is the greatest Duplex Gate Valve Supplier in Jordan. It is a type of valve that is primarily used to control the flow of fluid through a pipeline. It is called “Duplex” because it is constructed from duplex stainless steel, a material known for its high strength, excellent corrosion resistance, and superior durability. These valves are widely used in industries where the fluid being transported is highly corrosive or where the valve needs to withstand high pressure and temperature.

The working principle of a Duplex Gate Valve involves a gate or wedge that moves perpendicular to the flow of the fluid. When the valve is in the open position, the gate is lifted out of the path of the fluid, allowing it to flow freely. When the valve is closed, the gate is lowered into the path of the fluid, creating a tight seal and preventing any flow. The gate is operated by a handwheel or an actuator, which can be manually or automatically controlled.

The primary function of a Duplex Gate Valve is to start or stop the flow of fluid in a pipeline. It is not designed to regulate the flow; it is either fully open or fully closed. This makes it ideal for applications where a full bore flow or a complete shut-off is required. Duplex Gate Valves are commonly used in the oil and gas industry, chemical processing plants, and water treatment facilities.

Features

1)Material: Made from duplex stainless steel, offering high strength and excellent corrosion resistance.

2)Design: Available in various designs such as rising stem, non-rising stem, and pressure-seal.

3)Operation: Can be operated manually or automatically using actuators.

4)Seal: Provides a tight seal when closed, preventing any leakage.

5)Durability: Highly durable and can withstand high pressure and temperature conditions.

6)Maintenance: Low maintenance requirements due to the robustness of the material.

Benefits

1)Strength: The high strength of duplex stainless steel ensures that the valve can handle high pressure and temperature conditions.

2)Longevity: The durability of the material extends the lifespan of the valve, reducing the need for frequent replacements.

3)Leak Prevention: The tight sealing capability of the valve prevents any leakage, ensuring the integrity of the pipeline.

4)Cost-Effective: Though initially more expensive, the long-term benefits and low maintenance requirements make it cost-effective.

Duplex Gate Valves are a reliable and efficient choice for controlling the flow of fluids in pipelines, especially in environments that demand high strength and corrosion resistance. Their robust design and material properties make them a preferred option in various industrial applications.