- Control Valve

- Pneumatic Control Valve

- Pneumatic Angle Control Valve

- 3 Way pneumatic Diaphragm Control Valve

- 3 Way Converging and Diverging Control Valve

- Fluorine Lined Single Seat Control Valve

- Pneumatic Cage Control Valve

- Pneumatic Double Seat Control Valve

- Pneumatic Single Seat Globe Control Valve

- Pneumatic Flow Control Valve

- Pneumatic Sleeve Type Control Valve

- Pneumatic Actuated Globe Type Control Valve

- Electric Actuated Control Valve

- Pneumatic Control Valve

- Cryogenic Valve

- Pressure Reducing Valve

- Safety Valve

- Check Valve

- Gate Valve

- Butterfly Valve

- Globe Valve

- Ball Valve

- Electric Actuated Valve

- Electric Actuated Ball Valve

- Electric Actuated Butterfly Valve

- Electric Actuated Gate Valve

- Electric Actuated Globe Valve

- Pneumatic Actuated Valve

- Plunger Valve

- Strainers

- Steam Trap

- Knife Gate Valve

- Speciality Valve

- Alloy 20 Valve

- Duplex Valve

- Super Duplex Valve

- Hastelloy C276/B3 Valve

- Aluminium Bronze Valve

- Titanium Valve

- Bronze Valve

- Monel Valve

- Triple Duty Valve

- Suction Diffuser

- Diaphragm Valve

- Plug Valve

- Foot Valve

- Air Release Valve

- Surge Anticipator Valve

- Needle Valve

- Balancing Valve

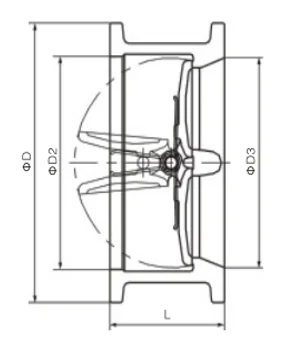

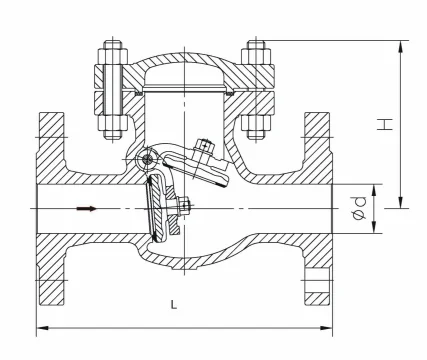

A Duplex Check Valve is a specialized valve designed to prevent reverse flow in a piping system. It typically incorporates a duplex steel body, offering superior resistance to corrosion and stress in extreme environments. The use of duplex materials makes these valves highly durable and suitable for applications where both strength and corrosion resistance are critical, such as in the oil and gas, chemical, and marine industries.

Function: The primary function of a Duplex Check Valve is to allow fluid to flow in one direction while automatically preventing backflow. This unidirectional flow control is crucial in ensuring system efficiency and protecting equipment like pumps from damage due to reverse flow. Unlike other valves that require manual operation, the Duplex Check Valve operates automatically in response to pressure changes.

Features:

1)High Corrosion Resistance: Thanks to the duplex stainless steel construction, these valves offer excellent resistance to corrosion, particularly in harsh environments like saltwater or chemical processing.

2)Superior Strength: The combination of austenitic and ferritic stainless steel gives the valve enhanced strength and durability.

3)Compact Design: Duplex Check Valves are often compact, making them suitable for systems with space constraints.

4)Low Maintenance: With fewer moving parts and automatic operation, the valve requires minimal maintenance.

Working: The Duplex Check Valve works based on the pressure differential between the inlet and outlet sides of the valve. When fluid flows in the correct direction, the pressure on the inlet side pushes the valve open, allowing flow. When the flow stops or reverses, the pressure on the outlet side exceeds the inlet pressure, causing the valve to close automatically. This closure prevents backflow, maintaining system integrity and protecting upstream equipment from damage.

The closing mechanism can be a swing disc, ball, or other types of internal components, which are pushed into place to block reverse flow as the pressure changes. Due to its duplex steel construction, the valve can withstand high pressure and temperatures, making it ideal for demanding applications.