- Control Valve

- Pneumatic Control Valve

- Pneumatic Angle Control Valve

- 3 Way pneumatic Diaphragm Control Valve

- 3 Way Converging and Diverging Control Valve

- Fluorine Lined Single Seat Control Valve

- Pneumatic Cage Control Valve

- Pneumatic Double Seat Control Valve

- Pneumatic Single Seat Globe Control Valve

- Pneumatic Flow Control Valve

- Pneumatic Sleeve Type Control Valve

- Pneumatic Actuated Globe Type Control Valve

- Electric Actuated Control Valve

- Pneumatic Control Valve

- Cryogenic Valve

- Pressure Reducing Valve

- Safety Valve

- Check Valve

- Gate Valve

- Butterfly Valve

- Globe Valve

- Ball Valve

- Electric Actuated Valve

- Electric Actuated Ball Valve

- Electric Actuated Butterfly Valve

- Electric Actuated Gate Valve

- Electric Actuated Globe Valve

- Pneumatic Actuated Valve

- Plunger Valve

- Strainers

- Steam Trap

- Knife Gate Valve

- Speciality Valve

- Alloy 20 Valve

- Duplex Valve

- Super Duplex Valve

- Hastelloy C276/B3 Valve

- Aluminium Bronze Valve

- Titanium Valve

- Bronze Valve

- Monel Valve

- Triple Duty Valve

- Suction Diffuser

- Diaphragm Valve

- Plug Valve

- Foot Valve

- Air Release Valve

- Surge Anticipator Valve

- Needle Valve

- Balancing Valve

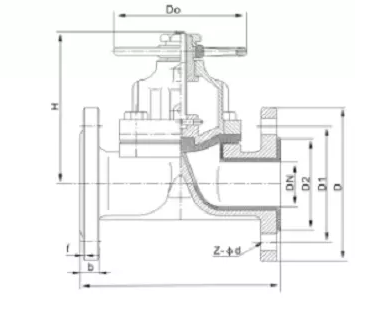

Middleeast valve is famous for Ductile Iron Diaphragm Valve Supplier in Saudi Arabia. It is a type of valve that regulates the flow of fluids through a system by means of a flexible diaphragm, typically made of rubber or other elastomeric materials. The valve body is constructed from ductile iron, known for its high tensile strength and durability, making it suitable for applications where robust performance is required.

Working: the operation of a diaphragm valve involves the movement of a diaphragm that is secured to a valve stem. When the valve is open, the diaphragm is lifted away from the seat, allowing fluid to pass through. Conversely, when the valve is closed, the diaphragm is pressed against the seat, stopping the flow. This action is typically controlled manually via a hand wheel or automatically using actuators.

The primary function of a ductile iron diaphragm valve is to control the flow of fluids, including liquids, gases, and slurries, in a pipeline. It can be used for both on/off and throttling service. The valve is designed to prevent contamination and ensure leak-tight performance, making it ideal for industries such as water treatment, and chemical processing.

Features:

1)Ductile Iron Construction: Offers high tensile strength and impact resistance, ensuring durability in demanding environments.

2)Flexible Diaphragm: Provides a tight seal, preventing leaks and contamination.

3)Corrosion Resistance: Suitable for handling a wide range of corrosive fluids.

4)Simple Operation: Can be operated manually or automatically, with easy maintenance.

Benefits:

1)Long Service Life: The durability of ductile iron and the design of the diaphragm contribute to an extended valve lifespan, reducing the need for frequent replacements.

2)Leak-Proof Performance: The diaphragm ensures a tight seal, minimizing the risk of leaks and enhancing operational safety.

3)Low Maintenance: The simple design with fewer moving parts leads to easier maintenance and lower operational costs.

This combination of features and benefits makes the ductile iron diaphragm valve a reliable choice for fluid control in various industrial applications.