- Control Valve

- Pneumatic Control Valve

- Pneumatic Angle Control Valve

- 3 Way pneumatic Diaphragm Control Valve

- 3 Way Converging and Diverging Control Valve

- Fluorine Lined Single Seat Control Valve

- Pneumatic Cage Control Valve

- Pneumatic Double Seat Control Valve

- Pneumatic Single Seat Globe Control Valve

- Pneumatic Flow Control Valve

- Pneumatic Sleeve Type Control Valve

- Pneumatic Actuated Globe Type Control Valve

- Electric Actuated Control Valve

- Pneumatic Control Valve

- Cryogenic Valve

- Pressure Reducing Valve

- Safety Valve

- Check Valve

- Gate Valve

- Butterfly Valve

- Globe Valve

- Ball Valve

- Electric Actuated Valve

- Electric Actuated Ball Valve

- Electric Actuated Butterfly Valve

- Electric Actuated Gate Valve

- Electric Actuated Globe Valve

- Pneumatic Actuated Valve

- Plunger Valve

- Strainers

- Steam Trap

- Knife Gate Valve

- Speciality Valve

- Alloy 20 Valve

- Duplex Valve

- Super Duplex Valve

- Hastelloy C276/B3 Valve

- Aluminium Bronze Valve

- Titanium Valve

- Bronze Valve

- Monel Valve

- Triple Duty Valve

- Suction Diffuser

- Diaphragm Valve

- Plug Valve

- Foot Valve

- Air Release Valve

- Surge Anticipator Valve

- Needle Valve

- Balancing Valve

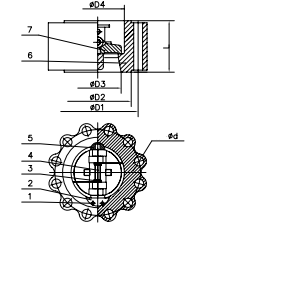

Dual Plate Check Valve

Middle East Valve is a well known Dual Plate Lug Check valve suppliers in UAE. They are used to stop fluids from flowing backward in pipelines. It is made up of two disc- that are hinged inside the valve body and have the shape of a half-moon. When the fluid moves in the intended direction, these plates swing open, reducing the amount of resistance the fluid faces as it passes through the valve. In contrast, if the fluid tries to flow in the opposite direction, the plates shut quickly, forming a tight barrier that stops backflow.

[expander_maker id=”1″ more=”Read more” less=”Read less”]

This design enables simple installation and maintenance of the system while providing a safe and leak-proof connection. They are perfect for applications where quick shutting and opening are essential because of the twin plate construction, which enables quick reaction to flow variations. These valves are recognized for their effectiveness because, when compared to other check valve designs, they minimize pressure drop and pipeline turbulence.

Advantages:

- Efficient Flow Control.

- Compact Design

- Low Pressure Drop

- High Flow Capacity

- Minimal Maintenance

- Secure Installation

- Long Service Life

- Reduced Water Hammer

Industries:

- Oil and Gas

- Petrochemical

- Water and Wastewater Treatment

- Power Generation

- Chemical Processing

- Mining

- Marine and Shipbuilding

- Fire Protection

Description:

- Body Material: Cast Iron, Ductile Iron, Cast Steel, Stainless Steel, Aluminium Bronze

- Disc: Ductile Iron, Stainless Steel, Aluminium Bronze

- Size: DN50 to DN900

- Nominal Pressure: Class 150 to Class 2500

- Flanged End Dimensions: ASME B16.10

[/expander_maker]