- Control Valve

- Pneumatic Control Valve

- Pneumatic Angle Control Valve

- 3 Way pneumatic Diaphragm Control Valve

- 3 Way Converging and Diverging Control Valve

- Fluorine Lined Single Seat Control Valve

- Pneumatic Cage Control Valve

- Pneumatic Double Seat Control Valve

- Pneumatic Single Seat Globe Control Valve

- Pneumatic Flow Control Valve

- Pneumatic Sleeve Type Control Valve

- Pneumatic Actuated Globe Type Control Valve

- Electric Actuated Control Valve

- Pneumatic Control Valve

- Cryogenic Valve

- Pressure Reducing Valve

- Safety Valve

- Check Valve

- Gate Valve

- Butterfly Valve

- Globe Valve

- Ball Valve

- Electric Actuated Valve

- Electric Actuated Ball Valve

- Electric Actuated Butterfly Valve

- Electric Actuated Gate Valve

- Electric Actuated Globe Valve

- Pneumatic Actuated Valve

- Plunger Valve

- Strainers

- Steam Trap

- Knife Gate Valve

- Speciality Valve

- Alloy 20 Valve

- Duplex Valve

- Super Duplex Valve

- Hastelloy C276/B3 Valve

- Aluminium Bronze Valve

- Titanium Valve

- Bronze Valve

- Monel Valve

- Triple Duty Valve

- Suction Diffuser

- Diaphragm Valve

- Plug Valve

- Foot Valve

- Air Release Valve

- Surge Anticipator Valve

- Needle Valve

- Balancing Valve

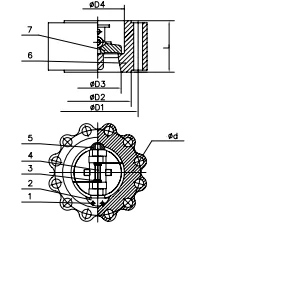

Middleeast Valve is the greatest Dual plate check valve manufacturers in Saudi Arabia. It is a type of non-return valve designed to prevent backflow in a piping system, ensuring that fluid only flows in one direction. It is commonly used in various industries such as oil and gas, petrochemical, water treatment, and power generation due to its compact design, reliability, and efficient operation.

Key Features of Dual Plate Check Valve:

1)Compact Design: Dual Plate Check Valves have a slim, wafer-like body that fits between flanges, minimizing the space required for installation. This makes them ideal for tight spaces and systems where weight is a concern.

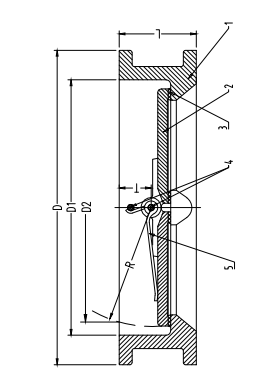

2)Two Plates: As the name suggests, these valves consist of two plates or discs that open and close based on the flow of fluid. The plates are hinged and spring-loaded, allowing them to shut quickly when the flow stops, thus preventing reverse flow.

3)Low Pressure Drop: The valve’s design ensures that the plates open fully with minimal fluid pressure, resulting in a low pressure drop across the valve, enhancing system efficiency.

4)Shock and Water Hammer Resistance: The valve’s spring-loaded mechanism ensures that the plates close smoothly, reducing the risk of water hammer, which is a common issue in systems with sudden flow reversals.

Applications of Dual Plate Check Valve:

1)Oil and Gas: These valves are widely used in pipelines transporting crude oil, natural gas, and refined products.

2)Water Treatment: Dual Plate Check Valves are utilized in water treatment plants to control the flow of water and prevent contamination from backflow.

3)Chemical Industry: The valves handle aggressive chemicals and abrasive materials, thanks to their durable construction.

Benefits of Using Dual Plate Check Valve:

1)Cost-Effective: With fewer moving parts and a compact structure, Dual Plate Check Valves are cost-efficient in terms of both installation and maintenance.

2)Reliable Backflow Prevention: The dual plates offer a quick and secure shut-off, ensuring a high level of reliability.

3)Energy Efficiency: The low-pressure drop design helps in maintaining the energy efficiency of the overall system.

4)Easy Installation: The lightweight and wafer-style design make them easy to install between flanges, saving time during maintenance or system upgrades.

The Dual Plate Check Valve is a versatile and essential component in many fluid systems. Its compact size, low pressure drop, and effective backflow prevention make it a go-to solution for industries requiring reliable fluid control. Whether it’s handling gases, liquids, or even slurries, the Dual Plate Check Valve is engineered to deliver efficient performance with minimal maintenance.