- Control Valve

- Pneumatic Control Valve

- Pneumatic Angle Control Valve

- 3 Way pneumatic Diaphragm Control Valve

- 3 Way Converging and Diverging Control Valve

- Fluorine Lined Single Seat Control Valve

- Pneumatic Cage Control Valve

- Pneumatic Double Seat Control Valve

- Pneumatic Single Seat Globe Control Valve

- Pneumatic Flow Control Valve

- Pneumatic Sleeve Type Control Valve

- Pneumatic Actuated Globe Type Control Valve

- Electric Actuated Control Valve

- Pneumatic Control Valve

- Cryogenic Valve

- Pressure Reducing Valve

- Safety Valve

- Check Valve

- Gate Valve

- Butterfly Valve

- Globe Valve

- Ball Valve

- Electric Actuated Valve

- Electric Actuated Ball Valve

- Electric Actuated Butterfly Valve

- Electric Actuated Gate Valve

- Electric Actuated Globe Valve

- Pneumatic Actuated Valve

- Plunger Valve

- Strainers

- Steam Trap

- Knife Gate Valve

- Speciality Valve

- Alloy 20 Valve

- Duplex Valve

- Super Duplex Valve

- Hastelloy C276/B3 Valve

- Aluminium Bronze Valve

- Titanium Valve

- Bronze Valve

- Monel Valve

- Triple Duty Valve

- Suction Diffuser

- Diaphragm Valve

- Plug Valve

- Foot Valve

- Air Release Valve

- Surge Anticipator Valve

- Needle Valve

- Balancing Valve

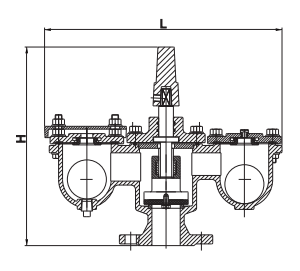

Double Orifice Air Release Valve Supplier in Oman: Efficient Air Venting for Pipeline Systems

Middleeast valve is the greatest Double orifice air release valve supplier in Oman. It is a specialized valve used in piping systems to automatically release air pockets that form within the system.

Working Mechanism:

At the time of system startup, the big float falls, allowing the big orifice to release air. With the filling of the pipeline with water, the float rises and closes the valve. Under working conditions, little air bubbles are constantly released through the small orifice by the little float. This double-purpose mechanism allows for a smooth and efficient pipeline system.

Benefits of Double Orifice Air Release Valve:

1)Avoids air lock and enhances flow efficiency

2)Reduces the danger of water hammer

3)Increases pipeline life

4)Automatically operates with low maintenance

5)Ideal for high-pressure and big-bore pipelines

Industries we serve:

1)Water Distribution

2)Wastewater Management

3)Irrigation Systems

4)Power Plants

Description:

Body Material- ductile iron, cast iron, WCB,WCC, WC6, LCB, LCC.

Size- 1/2’’ to 8’’

Pressure No- PN6 to PN25,

Class- 150 to 300.