- Control Valve

- Pneumatic Control Valve

- Pneumatic Angle Control Valve

- 3 Way pneumatic Diaphragm Control Valve

- 3 Way Converging and Diverging Control Valve

- Fluorine Lined Single Seat Control Valve

- Pneumatic Cage Control Valve

- Pneumatic Double Seat Control Valve

- Pneumatic Single Seat Globe Control Valve

- Pneumatic Flow Control Valve

- Pneumatic Sleeve Type Control Valve

- Pneumatic Actuated Globe Type Control Valve

- Electric Actuated Control Valve

- Pneumatic Control Valve

- Cryogenic Valve

- Pressure Reducing Valve

- Safety Valve

- Check Valve

- Gate Valve

- Butterfly Valve

- Globe Valve

- Ball Valve

- Electric Actuated Valve

- Electric Actuated Ball Valve

- Electric Actuated Butterfly Valve

- Electric Actuated Gate Valve

- Electric Actuated Globe Valve

- Pneumatic Actuated Valve

- Plunger Valve

- Strainers

- Steam Trap

- Knife Gate Valve

- Speciality Valve

- Alloy 20 Valve

- Duplex Valve

- Super Duplex Valve

- Hastelloy C276/B3 Valve

- Aluminium Bronze Valve

- Titanium Valve

- Bronze Valve

- Monel Valve

- Triple Duty Valve

- Suction Diffuser

- Diaphragm Valve

- Plug Valve

- Foot Valve

- Air Release Valve

- Surge Anticipator Valve

- Needle Valve

- Balancing Valve

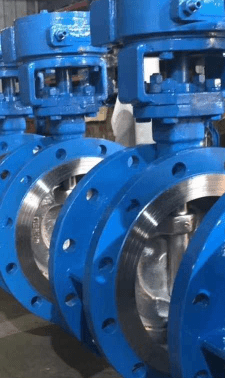

Double Flanged Butterfly Valve

Middleeast valve is the largest Double Flanged Butterfly Valve suppliers in Saudi Arabia. A double flanged butterfly valve is a type of valve used to regulate the flow of fluid through a pipe.

The term “double flanged” refers to the presence of flanges on both sides of the valve, which are used for mounting the valve between pipe flanges. This design ensures a secure, leak-proof connection and allows for easy installation and removal. The butterfly valve is characterized by its circular disc or vane, which rotates to control the flow of fluid.

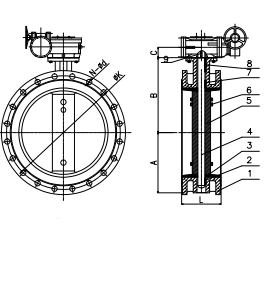

The working theory of a double flanged butterfly valve is based on the movement of its disc, which acts as the closing mechanism. The disc is positioned in the center of the pipe and is connected to an actuator on the outside of the valve. When the actuator is turned, it rotates the disc either parallel or perpendicular to the flow of the fluid.

Open Position: When the disc is turned parallel to the flow, the valve is fully open, allowing fluid to pass through with minimal resistance.

Closed Position: When the disc is turned perpendicular to the flow, it creates a seal with the valve body, effectively stopping the flow.

The simplicity of this mechanism allows for quick operation, making butterfly valves ideal for applications requiring frequent opening and closing.

Double flanged butterfly valves serve several essential functions in various industries, including water treatment, chemical processing, and power generation. Their primary functions include:

Flow Regulation: They provide precise control over the flow of fluids, which can be crucial for maintaining system efficiency and safety.

Isolation: They can isolate sections of a pipeline for maintenance or in emergency situations, ensuring that the rest of the system remains operational.

Throttling: By partially opening or closing the disc, butterfly valves can be used to throttle fluid flow, providing a controlled flow rate as required.

Applications:

Robust Construction: The double flanged design ensures a robust and secure connection between the valve and the pipeline. This design minimizes the risk of leaks and makes the valve suitable for high-pressure applications.

Compact Design: Butterfly valves are known for their compact and lightweight design compared to other types of valves like gate or globe valves. This compactness makes them ideal for installations where space is limited.

Easy Installation and Maintenance: The double flanged connection allows for straightforward installation and removal. Maintenance is simplified as the valve can be easily accessed and serviced without requiring extensive downtime.

Double flanged butterfly valve suppliers in Saudi Arabia are a vital component in modern fluid control systems, offering a combination of robust construction, versatility, and cost-effectiveness.

Description:

Available materials: Cast iron, Ductile iron, SS304, SS316, WCB,WCC,WC6, LCB, LCC, SS316L, F55, F53, F51

Size: 2” to 72”

Class: 150 to 300

Nominal Pressure: PN6 to PN25

Ends: Flanged

Operations: Gear Operated, Electric and Pneumatic Actuated, Lever Operated

Standards: ASME, API6D, API607, DIN, BS, ANSI, AWWA