- Control Valve

- Pneumatic Control Valve

- Pneumatic Angle Control Valve

- 3 Way pneumatic Diaphragm Control Valve

- 3 Way Converging and Diverging Control Valve

- Fluorine Lined Single Seat Control Valve

- Pneumatic Cage Control Valve

- Pneumatic Double Seat Control Valve

- Pneumatic Single Seat Globe Control Valve

- Pneumatic Flow Control Valve

- Pneumatic Sleeve Type Control Valve

- Pneumatic Actuated Globe Type Control Valve

- Electric Actuated Control Valve

- Pneumatic Control Valve

- Cryogenic Valve

- Pressure Reducing Valve

- Safety Valve

- Check Valve

- Gate Valve

- Butterfly Valve

- Globe Valve

- Ball Valve

- Electric Actuated Valve

- Electric Actuated Ball Valve

- Electric Actuated Butterfly Valve

- Electric Actuated Gate Valve

- Electric Actuated Globe Valve

- Pneumatic Actuated Valve

- Plunger Valve

- Strainers

- Steam Trap

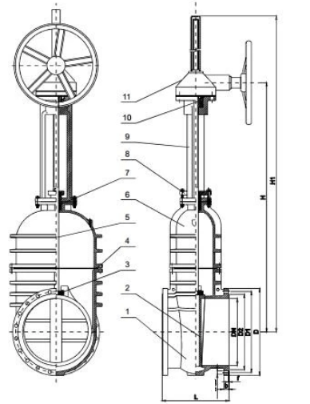

- Knife Gate Valve

- Speciality Valve

- Alloy 20 Valve

- Duplex Valve

- Super Duplex Valve

- Hastelloy C276/B3 Valve

- Aluminium Bronze Valve

- Titanium Valve

- Bronze Valve

- Monel Valve

- Triple Duty Valve

- Suction Diffuser

- Diaphragm Valve

- Plug Valve

- Foot Valve

- Air Release Valve

- Surge Anticipator Valve

- Needle Valve

- Balancing Valve

A Double Disc Gate Valve is a type of gate valve that utilizes two discs to control the flow of fluid within a pipeline. The design is particularly suited for applications requiring a high degree of sealing performance and reliability. These valves are commonly used in industries like oil and gas, water treatment, and power generation, where ensuring a leak-proof seal is crucial.

The Double Disc Gate Valve operates by raising and lowering the two parallel discs within the valve body to control fluid flow. When the valve is fully open, the discs are lifted into the valve bonnet, allowing unrestricted flow through the pipeline. When closed, the discs are pressed against the valve seats, creating a tight seal to stop the flow. The pressure from the fluid helps in enhancing the sealing, ensuring that the valve remains leak-proof even under high-pressure conditions.

Features:

1)Parallel Discs: The valve incorporates two parallel discs that provide a robust sealing mechanism.

2)Rising or Non-Rising Stem: Depending on the design, the stem of the valve may rise or stay in place when the valve is operated, helping in space management and maintenance.

3)Bi-Directional Flow: Allows flow in both directions, providing versatility in pipeline operations.

4)Flexible Wedge: The discs often feature a flexible wedge design to accommodate thermal expansion and prevent jamming.

5)Pressure Sealed Bonnet: Ensures that the valve remains leak-proof even under high-pressure conditions.

6)Corrosion-Resistant Materials: Typically made from materials like stainless steel or carbon steel to resist corrosion and wear.

Benefits:

1)Enhanced Sealing: The double-disc design provides superior sealing, reducing the risk of leakage.

2)Long Service Life: The robust construction and high-quality materials used in these valves ensure a long operational life, even in harsh environments.

3)Reduced Maintenance: With fewer moving parts and a reliable sealing mechanism, these valves require less frequent maintenance.

4)Energy Efficiency: The tight seal provided by the double discs minimizes energy loss due to leakage, enhancing overall system efficiency.

Functions:

1)Flow Regulation: Controls the flow of fluids in pipelines by opening or closing the passage.

2)Isolation: Provides a reliable shut-off mechanism to isolate sections of the pipeline for maintenance or emergency situations.

3)Pressure Control: Helps in managing and controlling the pressure within the pipeline, ensuring system safety.

4)Direction Control: Allows for the controlled flow of fluid in either direction, depending on the needs of the system.

5)Leak Prevention: Ensures that the system remains leak-proof, maintaining operational efficiency and safety.

Double Disc Gate Valves are critical components in industrial systems, offering reliable flow control, enhanced sealing, and long-term durability. Their design makes them ideal for applications where precision and reliability are paramount.