- Control Valve

- Pneumatic Control Valve

- Pneumatic Angle Control Valve

- 3 Way pneumatic Diaphragm Control Valve

- 3 Way Converging and Diverging Control Valve

- Fluorine Lined Single Seat Control Valve

- Pneumatic Cage Control Valve

- Pneumatic Double Seat Control Valve

- Pneumatic Single Seat Globe Control Valve

- Pneumatic Flow Control Valve

- Pneumatic Sleeve Type Control Valve

- Pneumatic Actuated Globe Type Control Valve

- Electric Actuated Control Valve

- Pneumatic Control Valve

- Cryogenic Valve

- Pressure Reducing Valve

- Safety Valve

- Check Valve

- Gate Valve

- Butterfly Valve

- Globe Valve

- Ball Valve

- Electric Actuated Valve

- Electric Actuated Ball Valve

- Electric Actuated Butterfly Valve

- Electric Actuated Gate Valve

- Electric Actuated Globe Valve

- Pneumatic Actuated Valve

- Plunger Valve

- Strainers

- Steam Trap

- Knife Gate Valve

- Speciality Valve

- Alloy 20 Valve

- Duplex Valve

- Super Duplex Valve

- Hastelloy C276/B3 Valve

- Aluminium Bronze Valve

- Titanium Valve

- Bronze Valve

- Monel Valve

- Triple Duty Valve

- Suction Diffuser

- Diaphragm Valve

- Plug Valve

- Foot Valve

- Air Release Valve

- Surge Anticipator Valve

- Needle Valve

- Balancing Valve

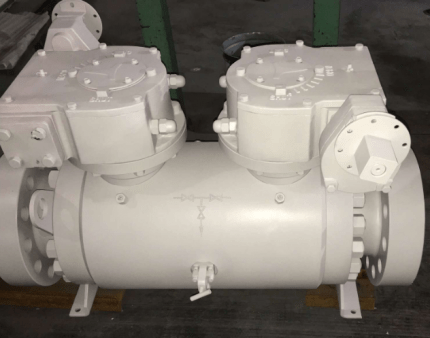

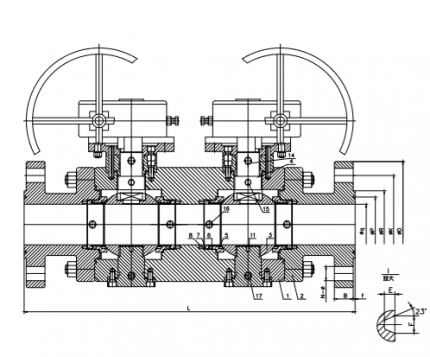

Middleeast valve is one of the best Double Block and Bleed Ball Valve supplier in Saudi Arabia. A Double Block and Bleed (DBB) Ball Valve is a specialized type of valve designed to ensure that there is no leakage when isolating a section of the pipeline. It incorporates two sealing surfaces (or “blocks”) and a bleed mechanism to vent the cavity between the blocks. This design ensures complete isolation of the pipeline section when necessary, providing a higher degree of safety and reliability in operations.

The working principle of a Double Block and Bleed Ball Valve involves the following steps:

1)Isolating the Flow: When the valve is in the closed position, the two seating surfaces provide a tight seal, isolating the downstream from the upstream flow.

2)Bleeding the Cavity: Once isolated, the cavity between the two seating surfaces is bled via the bleed mechanism. 3)This ensures that any fluid trapped between the two seats is safely vented, confirming the integrity of the seals.

4)Maintaining Isolation: The valve ensures that there is no leakage past either of the seating surfaces, maintaining complete isolation.

Function: the primary function of a Double Block and Bleed Ball Valve is to isolate a section of the pipeline while providing a means to safely vent any trapped fluid. This is critical in applications requiring stringent isolation and safety standards, such as in the oil and gas, petrochemical, and refining industries.

Features:

1)Dual Sealing Surfaces: Two independent sealing surfaces ensure robust isolation.

2)Bleed Mechanism: A bleed valve or vent system to release trapped fluid between the seals.

3)Metal-to-Metal or Soft Seals: Depending on the application, the seals can be metal-to-metal or soft seals, providing flexibility in use.

4)High-Integrity Construction: Designed to withstand high pressures and harsh operating conditions.

5)Pneumatic, or Electric Actuation: Versatile actuation options to suit different operational needs.

Benefits:

1)Enhanced Safety: Provides reliable isolation, reducing the risk of accidental leaks and ensuring safe maintenance operations.

2)Operational Efficiency: Enables maintenance without shutting down the entire system, improving uptime and productivity.

3)Leak Detection: The bleed mechanism allows for the detection of leaks, ensuring the integrity of the isolation.

A Double Block and Bleed Ball Valve supplier in Saudi Arabia is an essential component in systems where safe and reliable isolation is critical. Its robust design and operational capabilities make it a preferred choice in many industries, ensuring both operational efficiency and safety.

Description:

Materials: Cast iron, Cast steel (WCB, WCC, WC6, WC9, LCB, LCC), Ductile iron, SS304, SS316

Class: PN10 to PN 450; 150 to 2500

Ends: Buttweld, Flanged, Socket weld, Threaded

Size: 1/2’’to 24’’

Operations: Electric Actuated, Pneumatic Actuated, Gear Operated, Handwheel Operated