- Control Valve

- Pneumatic Control Valve

- Pneumatic Angle Control Valve

- 3 Way pneumatic Diaphragm Control Valve

- 3 Way Converging and Diverging Control Valve

- Fluorine Lined Single Seat Control Valve

- Pneumatic Cage Control Valve

- Pneumatic Double Seat Control Valve

- Pneumatic Single Seat Globe Control Valve

- Pneumatic Flow Control Valve

- Pneumatic Sleeve Type Control Valve

- Pneumatic Actuated Globe Type Control Valve

- Electric Actuated Control Valve

- Pneumatic Control Valve

- Cryogenic Valve

- Pressure Reducing Valve

- Safety Valve

- Check Valve

- Gate Valve

- Butterfly Valve

- Globe Valve

- Ball Valve

- Electric Actuated Valve

- Electric Actuated Ball Valve

- Electric Actuated Butterfly Valve

- Electric Actuated Gate Valve

- Electric Actuated Globe Valve

- Pneumatic Actuated Valve

- Plunger Valve

- Strainers

- Steam Trap

- Knife Gate Valve

- Speciality Valve

- Alloy 20 Valve

- Duplex Valve

- Super Duplex Valve

- Hastelloy C276/B3 Valve

- Aluminium Bronze Valve

- Titanium Valve

- Bronze Valve

- Monel Valve

- Triple Duty Valve

- Suction Diffuser

- Diaphragm Valve

- Plug Valve

- Foot Valve

- Air Release Valve

- Surge Anticipator Valve

- Needle Valve

- Balancing Valve

Diaphragm Valve Manufacturers in Saudi Arabia: Leak-Proof Flow Control

Middleeast valve is the best Diaphragm Valve manufacturers in Saudi Arabia. It is a type of valve that uses a flexible diaphragm or membrane to control the flow of fluid through a pipe or tubing system.

It is a type of valve employed to regulate, isolate or control flow of fluid in any system. It contains flexible diaphragm which works as seal, which comes up and down to close or open valve. This type of arrangement provides tight shutoff, thus making it suitable to deal with corrosive, viscous or slurry type of fluid.

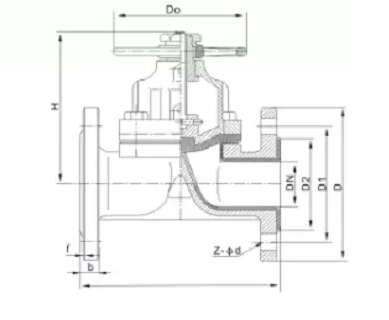

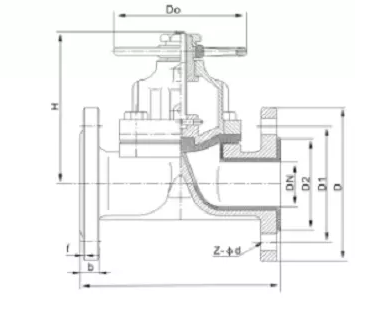

Components of Diaphragm Valve:

1)Body – Central part containing all the other parts.

2)Diaphragm – The elastic component that regulates the flow of the medium.

3)Actuator – A device that actuates the diaphragm, either by hand or by automation.

4)Bonnet – A cover that safeguards the actuator and diaphragm.

5)Stem – A rod linking the actuator and diaphragm.

Working Mechanism:

The diaphragm valve work on the principle of utilizing actuator to apply pressure on diaphragm. When actuator is activated, diaphragm push against valve body, obstructing flow path. When actuator is deactivated, diaphragm is lifted, permitting fluid to flow through.

Benefits of Using Diaphragm Valve:

1)Leak tight performance: Diaphragm provide tight sealing with very little leakage.

2)Corrosion resistance: Suitable for aggressive and corrosive fluids.

3)Easy to maintain: Simple design minimizes maintenance requirements.

Industries:

1)Chemical processing Industry

2)Water and Wastewater Treatment Plants

3)Pulp and Paper Industry

4)Power generation Plants

5)Oil and Gas Industry

6)Mining Industry

7)Marine Industry

Description:

Available Materials: Cast Iron, Ductile Iron, Alloy 20, WCB, WC6, WCC, LCB, LCC , SS304, SS316, CF8, CF8M

Class: 150 to 600

Nominal Pressure: PN10 to PN100

Size: 1” to 48”

Ends: Flanged, Threaded

Operation: Hand Wheel, electric actuated, pneumatic actuated, Gear operated