- Control Valve

- Pneumatic Control Valve

- Pneumatic Angle Control Valve

- 3 Way pneumatic Diaphragm Control Valve

- 3 Way Converging and Diverging Control Valve

- Fluorine Lined Single Seat Control Valve

- Pneumatic Cage Control Valve

- Pneumatic Double Seat Control Valve

- Pneumatic Single Seat Globe Control Valve

- Pneumatic Flow Control Valve

- Pneumatic Sleeve Type Control Valve

- Pneumatic Actuated Globe Type Control Valve

- Electric Actuated Control Valve

- Pneumatic Control Valve

- Cryogenic Valve

- Pressure Reducing Valve

- Safety Valve

- Check Valve

- Gate Valve

- Butterfly Valve

- Globe Valve

- Ball Valve

- Electric Actuated Valve

- Electric Actuated Ball Valve

- Electric Actuated Butterfly Valve

- Electric Actuated Gate Valve

- Electric Actuated Globe Valve

- Pneumatic Actuated Valve

- Plunger Valve

- Strainers

- Steam Trap

- Knife Gate Valve

- Speciality Valve

- Alloy 20 Valve

- Duplex Valve

- Super Duplex Valve

- Hastelloy C276/B3 Valve

- Aluminium Bronze Valve

- Titanium Valve

- Bronze Valve

- Monel Valve

- Triple Duty Valve

- Suction Diffuser

- Diaphragm Valve

- Plug Valve

- Foot Valve

- Air Release Valve

- Surge Anticipator Valve

- Needle Valve

- Balancing Valve

Cryogenic valve suppliers in UAE: Reliable Solutions for Ultra-Low Temperatures

Middleeast valve is topmost Cryogenic Valve Suppliers in UAE. It plays a crucial role in controlling the flow of these substances and maintaining the safety and efficiency of cryogenic processes. These valves are critical for maintaining the integrity and safety of cryogenic systems and ensuring that these super cooled substances are managed efficiently.

Parts of a Cryogenic Valve:

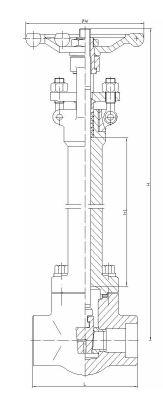

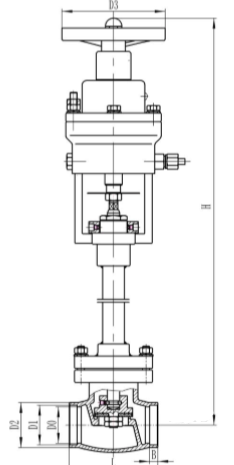

1)Bonnet: A longer bonnet, one of the most critical parts of cryogenic valves, keeps the stem cold.

2)Valve Body: Trim and body are made of stainless steel or other cold-insensitive materials.

3)Seals: Shut-off by sealing system avoids leaks.

4)Actuator or handwheel: Manual or automated.

Types:

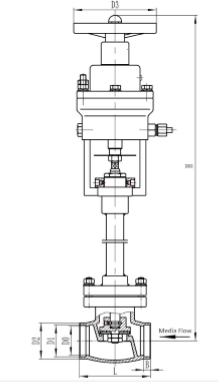

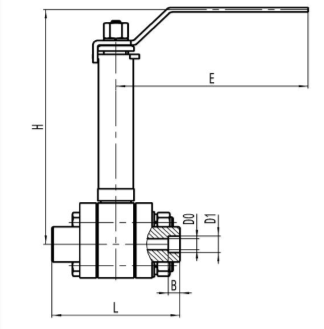

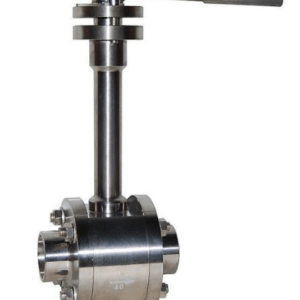

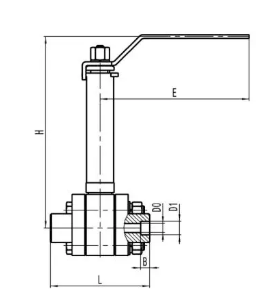

1)Cryogenic Ball Valve

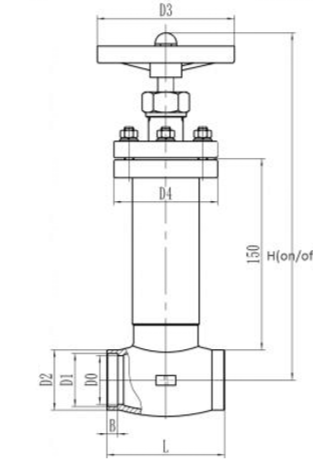

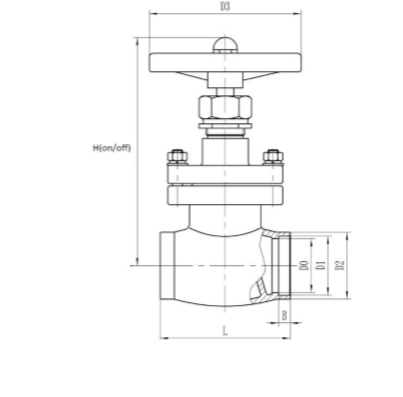

2)Cryogenic Globe Valve

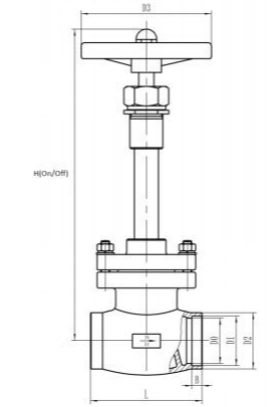

3)Cryogenic Gate Valve

4)Cryogenic Relief Valve

5)Cryogenic Butterfly Valve

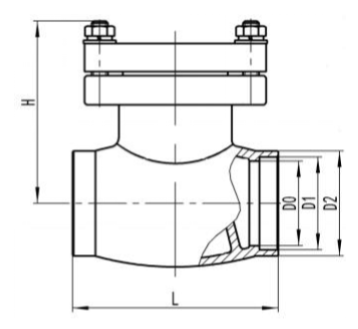

6)Cryogenic Check Valve

Benefits of Using Cryogenic Valve:

1)Designed for ultra-low temperatures

2)Improved safety features

3)Leak-free operation

4)Long lifespan

5)Low thermal loss

Industries:

1)Oil and Gas Industry

2)Marine Industry

3)Petrochemical Industry

4)Aerospace Industry

5)Chemical Industry

Description:

Available materials: SS304, SS316, CF8M, CF8, F51, F55, F53, WCB, WC6, WCC, LCB, LCC

Class: 150 to 800

Nominal Pressure: PN25 to PN100

Size: 1/2” to 24”

Ends- Flanged, Threaded, Socket weld, Butt weld.

Operations: Lever Operated , Hand wheel operated , Electric Actuated and Pneumatic Actuated.