- Control Valve

- Pneumatic Control Valve

- Pneumatic Angle Control Valve

- 3 Way pneumatic Diaphragm Control Valve

- 3 Way Converging and Diverging Control Valve

- Fluorine Lined Single Seat Control Valve

- Pneumatic Cage Control Valve

- Pneumatic Double Seat Control Valve

- Pneumatic Single Seat Globe Control Valve

- Pneumatic Flow Control Valve

- Pneumatic Sleeve Type Control Valve

- Pneumatic Actuated Globe Type Control Valve

- Electric Actuated Control Valve

- Pneumatic Control Valve

- Cryogenic Valve

- Pressure Reducing Valve

- Safety Valve

- Check Valve

- Gate Valve

- Butterfly Valve

- Globe Valve

- Ball Valve

- Electric Actuated Valve

- Electric Actuated Ball Valve

- Electric Actuated Butterfly Valve

- Electric Actuated Gate Valve

- Electric Actuated Globe Valve

- Pneumatic Actuated Valve

- Plunger Valve

- Strainers

- Steam Trap

- Knife Gate Valve

- Speciality Valve

- Alloy 20 Valve

- Duplex Valve

- Super Duplex Valve

- Hastelloy C276/B3 Valve

- Aluminium Bronze Valve

- Titanium Valve

- Bronze Valve

- Monel Valve

- Triple Duty Valve

- Suction Diffuser

- Diaphragm Valve

- Plug Valve

- Foot Valve

- Air Release Valve

- Surge Anticipator Valve

- Needle Valve

- Balancing Valve

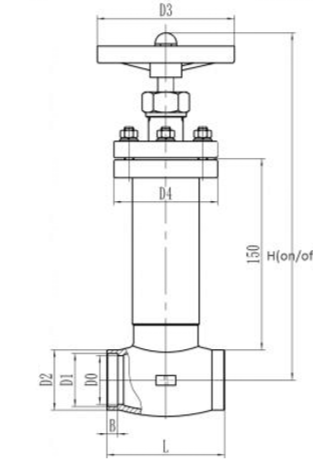

Cryogenic Steam Jacket Globe Valve in Riyadh – Effective Flow Control

Middleeast valve is the largest Cryogenic Steam Jacket Globe Valve in Riyadh. It has high-quality valve solutions intended for cryogenic applications. Our knowledge in offering strong and reliable valves guarantee smooth system operation that deal with very low temperature, especially in industries where control of cryogenic fluid is vital.

A Cryogenic Steam Jacket Globe Valve is specifically designed to control cryogenic liquid flow at the specified temperature within pipelines. The valves are equipped with a steam jacket over the valve body to avoid freezing and valve smoothness in low temperatures.

Key Components:

1)Valve Body: Made of materials that can resist the harsh condition of cryogenic environments.

2)Steam Jacket: A major component that encircles the valve body, sending steam around it to avoid freezing the valve and maintain good operation.

3)Stem and Disc: The moving components that open or close the valve to regulate the flow.

4)Seat and Seal: Provide a close seal to avoid leakage and preserve valve integrity.

5)Bonnet and Packing: The bonnet covers the stem, and the packing produces a leak-tight, uniform seal at cryogenic conditions.

Working Mechanism:

Cryogenic Steam Jacket Globe Valve functions by utilizing a steam jacket encircling the valve body to avoid the valve freezing as a result of the very low temperatures of the cryogenic liquids or gases. The steam jacket is used in circulating steam around the valve body, regulating the temperature level and avoiding erratic functioning. The disc and stem are used in opening or closing the valve, regulating the cryogenic liquids or gases’ motion.

Advantages:

1)Freezing Prevention: Steam jacket prevents valve freezing, allowing trouble-free operation under adverse conditions.

2)Precession Control: Provides accurate control of flow, necessary in the handling of cryogenic fluids.

3)Improved Safety: Offers a reliable and safe answer for high-hazard cryogenic service.

4)Improved Performance over a Long Period of Time: Operates under even the most severe cryogenic environments with low upkeep needs.

Industries:

1)LNG

2)Oil and gas

3)Chemical processing

4)Aerospace