- Control Valve

- Pneumatic Control Valve

- Pneumatic Angle Control Valve

- 3 Way pneumatic Diaphragm Control Valve

- 3 Way Converging and Diverging Control Valve

- Fluorine Lined Single Seat Control Valve

- Pneumatic Cage Control Valve

- Pneumatic Double Seat Control Valve

- Pneumatic Single Seat Globe Control Valve

- Pneumatic Flow Control Valve

- Pneumatic Sleeve Type Control Valve

- Pneumatic Actuated Globe Type Control Valve

- Electric Actuated Control Valve

- Pneumatic Control Valve

- Cryogenic Valve

- Pressure Reducing Valve

- Safety Valve

- Check Valve

- Gate Valve

- Butterfly Valve

- Globe Valve

- Ball Valve

- Electric Actuated Valve

- Electric Actuated Ball Valve

- Electric Actuated Butterfly Valve

- Electric Actuated Gate Valve

- Electric Actuated Globe Valve

- Pneumatic Actuated Valve

- Plunger Valve

- Strainers

- Steam Trap

- Knife Gate Valve

- Speciality Valve

- Alloy 20 Valve

- Duplex Valve

- Super Duplex Valve

- Hastelloy C276/B3 Valve

- Aluminium Bronze Valve

- Titanium Valve

- Bronze Valve

- Monel Valve

- Triple Duty Valve

- Suction Diffuser

- Diaphragm Valve

- Plug Valve

- Foot Valve

- Air Release Valve

- Surge Anticipator Valve

- Needle Valve

- Balancing Valve

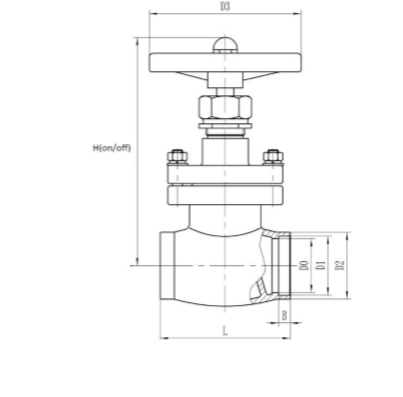

Cryogenic Short Stem Globe Valve Supplier in Dammam: Precision Flow Solutions for Cryogenic Applications

Middleeast Valve is a major distributor of the Cryogenic Short Stem Globe Valve Supplier in Dammam and provides high-end and high-performance products for industrial cryogenic low-temperature system applications. Our products are designed to ensure safe, efficient, and reliable operation and deliver the best performance in cryogenic systems.

A Cryogenic Short Stem Globe Valve is a valve specially developed to control the cryogenic liquids and gases flowing at very low temperatures.

Key Components:

1)Valve Body: The rugged housing that surrounds all the internal parts and is specially developed to survive ultra-low temperatures.

2)Short Stem: One of the other major characteristics of this valve, short stem design keeps the height of the valve low without compromising on performance levels.

3)Seat and Seal: These ensure good shut-off of the valve and leak tightness in cryogenic control of fluids.

4)Disc/Plug: The part that moves to regulate the flow by opening or closing against the seat valve.

5)Bonnet and Stem Packing: The bonnet gives the valve’s top cover, while packing provides a leakage-free seal in order to avoid leakage in cryogenic service.

Working Mechanism:

The Cryogenic Short Stem Globe Valve operates by changing the position of the plug or disc within the valve body. When the valve is actuated, the stem drives the plug towards or away from the seat, controlling the flow of cryogenic fluids.

Advantages:

1)Space-Saving Design

2)Precise Flow Control

3)Enhanced Safety

4)Low maintenance

5)High Longevity

Industries:

1)LNG

2)Petrochemicals

3)Aerospace

4)Chemical Industry