- Control Valve

- Pneumatic Control Valve

- Pneumatic Angle Control Valve

- 3 Way pneumatic Diaphragm Control Valve

- 3 Way Converging and Diverging Control Valve

- Fluorine Lined Single Seat Control Valve

- Pneumatic Cage Control Valve

- Pneumatic Double Seat Control Valve

- Pneumatic Single Seat Globe Control Valve

- Pneumatic Flow Control Valve

- Pneumatic Sleeve Type Control Valve

- Pneumatic Actuated Globe Type Control Valve

- Electric Actuated Control Valve

- Pneumatic Control Valve

- Cryogenic Valve

- Pressure Reducing Valve

- Safety Valve

- Check Valve

- Gate Valve

- Butterfly Valve

- Globe Valve

- Ball Valve

- Electric Actuated Valve

- Electric Actuated Ball Valve

- Electric Actuated Butterfly Valve

- Electric Actuated Gate Valve

- Electric Actuated Globe Valve

- Pneumatic Actuated Valve

- Plunger Valve

- Strainers

- Steam Trap

- Knife Gate Valve

- Speciality Valve

- Alloy 20 Valve

- Duplex Valve

- Super Duplex Valve

- Hastelloy C276/B3 Valve

- Aluminium Bronze Valve

- Titanium Valve

- Bronze Valve

- Monel Valve

- Triple Duty Valve

- Suction Diffuser

- Diaphragm Valve

- Plug Valve

- Foot Valve

- Air Release Valve

- Surge Anticipator Valve

- Needle Valve

- Balancing Valve

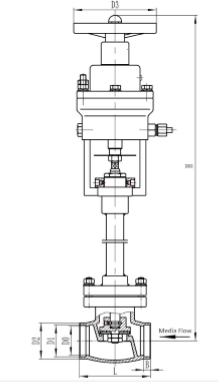

Middleeast valve is the leading Cryogenic Pneumatic Actuated Globe Valve Supplier in Doha. It is a specialized control valve designed for precise flow regulation in cryogenic applications, where extremely low temperatures are encountered, such as in the handling of liquefied gases like LNG, liquid nitrogen, oxygen, and helium. These valves are essential in industries such as oil and gas, chemical processing, and aerospace, where maintaining the integrity of cryogenic fluids is critical.

Key Features:

1)Material Compatibility: Constructed from materials like stainless steel or bronze, these valves are capable of withstanding cryogenic temperatures as low as -196°C (-321°F). Special low-temperature seals and packing materials prevent leakage and ensure reliable operation over a long lifespan.

2)Pneumatic Actuation: Equipped with a pneumatic actuator, the valve allows for automated control, enabling quick and accurate response to process control signals. Pneumatic actuation ensures safe operation in hazardous environments, as it eliminates the risk of electrical sparks.

3)Globe Valve Design: The globe valve configuration offers superior throttling capabilities, making it ideal for precise flow control. The design minimizes the pressure drop across the valve while maintaining excellent sealing when fully closed.

4)Extended Bonnet: The valve features an extended bonnet design, which provides insulation between the cryogenic fluid and the actuator. This prevents freezing of the actuator and ensures that the valve operates smoothly even at low temperatures.

5)Reliability and Safety: Designed to meet stringent industry standards, these valves ensure safe and reliable operation in critical applications. Built with fail-safe features to maintain safety and control in the event of a power or air supply failure.

Applications:

1)Liquefied Natural Gas (LNG) Processing: Used to control the flow of LNG in processing, transportation, and storage facilities.

2)Aerospace: Essential in managing the flow of cryogenic propellants like liquid oxygen and liquid hydrogen in rocket engines.

3)Cryogenic Storage: Utilized in tanks and containers that store cryogenic liquids to regulate and maintain the desired pressure and flow.

Cryogenic Pneumatic Actuated Globe Valves are crucial components in systems where the control of cryogenic fluids is required. Their robust construction, precise control, and safety features make them indispensable in industries where temperature extremes are a factor, ensuring that processes run smoothly and safely.