- Control Valve

- Pneumatic Control Valve

- Pneumatic Angle Control Valve

- 3 Way pneumatic Diaphragm Control Valve

- 3 Way Converging and Diverging Control Valve

- Fluorine Lined Single Seat Control Valve

- Pneumatic Cage Control Valve

- Pneumatic Double Seat Control Valve

- Pneumatic Single Seat Globe Control Valve

- Pneumatic Flow Control Valve

- Pneumatic Sleeve Type Control Valve

- Pneumatic Actuated Globe Type Control Valve

- Electric Actuated Control Valve

- Pneumatic Control Valve

- Cryogenic Valve

- Pressure Reducing Valve

- Safety Valve

- Check Valve

- Gate Valve

- Butterfly Valve

- Globe Valve

- Ball Valve

- Electric Actuated Valve

- Electric Actuated Ball Valve

- Electric Actuated Butterfly Valve

- Electric Actuated Gate Valve

- Electric Actuated Globe Valve

- Pneumatic Actuated Valve

- Plunger Valve

- Strainers

- Steam Trap

- Knife Gate Valve

- Speciality Valve

- Alloy 20 Valve

- Duplex Valve

- Super Duplex Valve

- Hastelloy C276/B3 Valve

- Aluminium Bronze Valve

- Titanium Valve

- Bronze Valve

- Monel Valve

- Triple Duty Valve

- Suction Diffuser

- Diaphragm Valve

- Plug Valve

- Foot Valve

- Air Release Valve

- Surge Anticipator Valve

- Needle Valve

- Balancing Valve

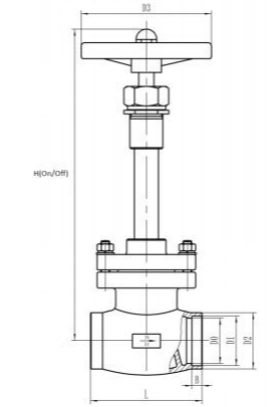

Cryogenic Long Stem Globe Valve Supplier in Kuwait – Trusted Solutions for Flow Control in Low-Temperature Industrial Systems

Middleeast valve is the foremost Cryogenic Long Stem Globe Valve Supplier in Kuwait. A Cryogenic Long Stem Globe Valve is specifically used for regulating cryogenic liquids and gases at very low temperatures. The long stem is more effective in isolating the valve mechanism from the harsh cold, thus allowing operation without being affected by thermal expansion that occurs in cryogenic systems.

Components:

1)Valve Body: Constructed using materials that can endure very low cryogenic temperatures.

2)Long Stem: The long stem creates a thermal barrier to keep the valve components from exposure to cryogenic temperatures, ensuring safe and smooth operation.

3)Disc/Plug: Disc or plug is the sealing mechanism that stops fluid flow by moving against the seat.

4)Seat and Seal: These components provide tight sealing, preventing leakage and ensuring flow control in extreme conditions.

5)Bonnet and Packing Stem: Bonnet houses the stem and has a packing arrangement to maintain an uninterrupted, leakage-free seal in difficult circumstances too.

Working Mechanism:

The Cryogenic Long Stem Globe Valve functions by varying the position of the disc against the seat of the valve. During the operation of the valve, the long stem provides insulation of the valve body from the very low temperatures, and the plug or disc opens or closes the valve in order to control the flow of cryogenic fluids. The valve is able to be precisely controlled, with very exact fluid control even under sub-zero conditions.

Advantages:

1)Compatibility at extreme temperatures

2)Accurate control of flow

3)Leak and safety prevention

4)Materials withstanding usage

Industries:

1)LNG

2)Oil and gas

3)Aerospace

4)Chemical processing

5)Research and Laboratories

6)Energy Industry