- Control Valve

- Pneumatic Control Valve

- Pneumatic Angle Control Valve

- 3 Way pneumatic Diaphragm Control Valve

- 3 Way Converging and Diverging Control Valve

- Fluorine Lined Single Seat Control Valve

- Pneumatic Cage Control Valve

- Pneumatic Double Seat Control Valve

- Pneumatic Single Seat Globe Control Valve

- Pneumatic Flow Control Valve

- Pneumatic Sleeve Type Control Valve

- Pneumatic Actuated Globe Type Control Valve

- Electric Actuated Control Valve

- Pneumatic Control Valve

- Cryogenic Valve

- Pressure Reducing Valve

- Safety Valve

- Check Valve

- Gate Valve

- Butterfly Valve

- Globe Valve

- Ball Valve

- Electric Actuated Valve

- Electric Actuated Ball Valve

- Electric Actuated Butterfly Valve

- Electric Actuated Gate Valve

- Electric Actuated Globe Valve

- Pneumatic Actuated Valve

- Plunger Valve

- Strainers

- Steam Trap

- Knife Gate Valve

- Speciality Valve

- Alloy 20 Valve

- Duplex Valve

- Super Duplex Valve

- Hastelloy C276/B3 Valve

- Aluminium Bronze Valve

- Titanium Valve

- Bronze Valve

- Monel Valve

- Triple Duty Valve

- Suction Diffuser

- Diaphragm Valve

- Plug Valve

- Foot Valve

- Air Release Valve

- Surge Anticipator Valve

- Needle Valve

- Balancing Valve

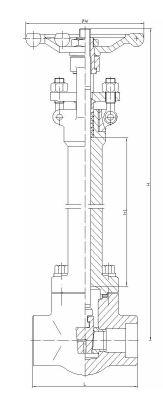

Cryogenic gate valve suppliers in Bahrain-Flow Isolation for Low-Temperature Systems

Middleeast valve is famous for Cryogenic gate valve suppliers in Bahrain. It is used in industries such as liquefied natural gas (LNG) production, aerospace, medical and scientific research, and any other applications that involve the handling and transportation of cryogenic liquids or gases.

Our cryogenic gate valves are intended to offer smooth flow control and safety in processes involving cryogenic fluids, performing at maximum potential even under most demanding conditions.

Key Components:

1)Valve Body: Made with high-strength materials to hold up against cryogenic temperatures and provide durability.

2)Gate (Disc): Vertical sliding component that opens or closes the valve, regulating the fluid flow.

3)Stem: Attaches the gate to the actuator and offers mechanical motion to run the valve.

4)Bonnet: Cover valve stem and offer thermal insulation, safeguarding internal component from harsh cold.

4)Seals and Packing: These are used to create tight seal to avoid leaks and preserve the integrity of the valve.

Working Mechanism:

The Cryogenic Gate Valve works by lifting or lowering the gate within the valve body. In the open position, the gate is moved out of the flow path so that the cryogenic fluid can flow through. In the closed position, the gate is moved into the flow path, obstructing the fluid. The gate and seal design provides leak-tight operation even in very low temperatures.

Advantages:

1)Leak-Free Operation: Offers dependable, tight sealing to avoid leakage, even under sub-zero conditions.

2)Accurate Flow Control: Perfect for precise flow control of cryogenic fluids.

3)Durability: Long lasting, require minimal maintenance, hence cost saving option for cryogenic system.

4)Thermal Insulation: Avoid freezing of internal part, ensuring smooth functioning in low temperature condition.

Industries:

1)LNG

2)Oil and gas

3)Chemical processing

4)Aerospace

5)Marine Industry

Description:

Available materials: SS306, SS904, SS316, Aluminium Bronze, Monel, Bronze, Brass, Duplex steel, Inconel, Incoloy, Titanium, WCB, CF8, CF8M, CF3, CF3M, WC1, WC6, WC9, Cast iron

Size: 1/2″- 64”

Class: 150 to 2500

Nominal Pressure: PN10 to PN450

Operation: Hand Wheel, Gear operated, Electric and Pneumatic Actuated

Ends: Flanged, Buttweld, Socket weld, Threaded