- Control Valve

- Pneumatic Control Valve

- Pneumatic Angle Control Valve

- 3 Way pneumatic Diaphragm Control Valve

- 3 Way Converging and Diverging Control Valve

- Fluorine Lined Single Seat Control Valve

- Pneumatic Cage Control Valve

- Pneumatic Double Seat Control Valve

- Pneumatic Single Seat Globe Control Valve

- Pneumatic Flow Control Valve

- Pneumatic Sleeve Type Control Valve

- Pneumatic Actuated Globe Type Control Valve

- Electric Actuated Control Valve

- Pneumatic Control Valve

- Cryogenic Valve

- Pressure Reducing Valve

- Safety Valve

- Check Valve

- Gate Valve

- Butterfly Valve

- Globe Valve

- Ball Valve

- Electric Actuated Valve

- Electric Actuated Ball Valve

- Electric Actuated Butterfly Valve

- Electric Actuated Gate Valve

- Electric Actuated Globe Valve

- Pneumatic Actuated Valve

- Plunger Valve

- Strainers

- Steam Trap

- Knife Gate Valve

- Speciality Valve

- Alloy 20 Valve

- Duplex Valve

- Super Duplex Valve

- Hastelloy C276/B3 Valve

- Aluminium Bronze Valve

- Titanium Valve

- Bronze Valve

- Monel Valve

- Triple Duty Valve

- Suction Diffuser

- Diaphragm Valve

- Plug Valve

- Foot Valve

- Air Release Valve

- Surge Anticipator Valve

- Needle Valve

- Balancing Valve

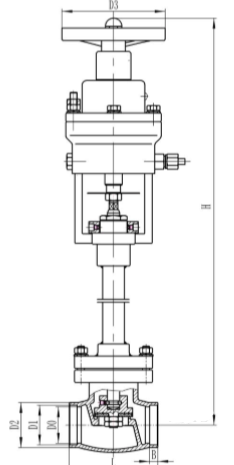

Cryogenic Emergency Cut-Off Valve Supplier in Kuwait: Ensuring Safety in Extreme Low-Temperature Applications

Middleeast Valve is a premier Cryogenic Emergency Cut-Off Valve Supplier in Kuwait. It is a solution provider with expertise in valves that guarantee the safety and integrity of systems used in very low temperatures. We utilize our technical know-how and dedication to the provision of high-quality products to assist industries in safely handling cryogenic processes and provide innovative solutions to address the most stringent needs.

Working Mechanism:

During regular operation, the valve is open to permit flow of the cryogenic fluids. During an emergency, e.g., system failure or unsafe pressure, the Cryogenic Emergency Cut-Off Valve closes automatically, stopping flow and avoiding possible damage or safety threat. The actuator is initiated by control signals to achieve quick and certain closure.

Key Parts:

1)Valve Body: The cover that contains all the internal parts and can withstand high temperatures.

2)Actuator: The system that drives the valve, normally pneumatic, electric, or hydraulic, based on the application.

3)Seat and Seal: Provides tight closure of the valve and maintains a seal during emergency operations.

4)Stem and Plug: The primary parts that are directly involved with cutting off or passing the cryogenic liquids and gases.

5)Spring Mechanism: Offers a return force to close the valve automatically when needed.

Advantages:

1)Safety Assurance: Offers emergency shut-off on occurrence of dangerous conditions, guaranteeing system integrity.

2)Reliability: Engineered to perform under extreme cryogenic conditions without failing.

3)Quick Response: The valve is capable of closing instantly to avoid accidents and leaks.

4)Minimal Maintenance: Needs low maintenance and a long life of operation.

Industries:

1)Oil and gas Industry

2)Aerospace

3)LNG

4)Cryogenic Storage Tanks

Description:

Available materials: SS304, SS316, CF8M, CF8, F51, F55, F53, WCB, WC6, WCC, LCB, LCC

Class: 150 to 800

Nominal Pressure: PN25 to PN100

Size: 1/2” to 24”

Ends- Flanged, Threaded, Socket weld, Butt weld.

Operations: Lever Operated , Hand wheel operated , Electric Actuated and Pneumatic Actuated.