- Control Valve

- Pneumatic Control Valve

- Pneumatic Angle Control Valve

- 3 Way pneumatic Diaphragm Control Valve

- 3 Way Converging and Diverging Control Valve

- Fluorine Lined Single Seat Control Valve

- Pneumatic Cage Control Valve

- Pneumatic Double Seat Control Valve

- Pneumatic Single Seat Globe Control Valve

- Pneumatic Flow Control Valve

- Pneumatic Sleeve Type Control Valve

- Pneumatic Actuated Globe Type Control Valve

- Electric Actuated Control Valve

- Pneumatic Control Valve

- Cryogenic Valve

- Pressure Reducing Valve

- Safety Valve

- Check Valve

- Gate Valve

- Butterfly Valve

- Globe Valve

- Ball Valve

- Electric Actuated Valve

- Electric Actuated Ball Valve

- Electric Actuated Butterfly Valve

- Electric Actuated Gate Valve

- Electric Actuated Globe Valve

- Pneumatic Actuated Valve

- Plunger Valve

- Strainers

- Steam Trap

- Knife Gate Valve

- Speciality Valve

- Alloy 20 Valve

- Duplex Valve

- Super Duplex Valve

- Hastelloy C276/B3 Valve

- Aluminium Bronze Valve

- Titanium Valve

- Bronze Valve

- Monel Valve

- Triple Duty Valve

- Suction Diffuser

- Diaphragm Valve

- Plug Valve

- Foot Valve

- Air Release Valve

- Surge Anticipator Valve

- Needle Valve

- Balancing Valve

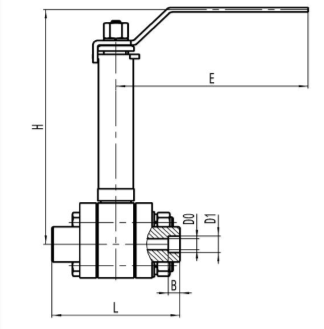

Cryogenic Ball Valve Supplier in Saudi Arabia – Specialized Valves for Low-Temperature Industrial Applications

Middleeast valve is the foremost Cryogenic ball valve supplier in Saudi Arabia. It offers high-performance and safe valve solutions for cryogenic fluid handling applications. Quality and safety-driven at our core, we offer cryogenic ball valves that guarantee effective, long-term performance even under the toughest conditions.

Cryogenic Ball valve are designed to function under extreme conditions, offering close sealing and efficient flow control in systems that operate under sub-zero temperatures.

Key Components:

1)Valve Body: Constructed of high-strength material to withstand the stringent conditions of cryogenic temperatures.

2)Ball: Spherical closing element that rotates for control of fluid flow. The spherical configuration minimizes wear and smooth flow control.

3)Seats and Seals: Ensure leak-tight service, keeping the fluid from leaking throughout operation.

4)Stem and Actuator: Stem link ball to actuator, and actuator drive ball to open or close valve.

5)Bonnet: Shields the internal parts of the valve from being damaged and facilitates smooth functioning.

Working Mechanism:

Cryogenic Ball Valves operate by turning the ball within the valve body. In an open state, the hole in the ball aligns with the pipeline and therefore fluid flow is enabled. During closure, the ball turns, and the hole misaligns with the pipeline and fluid flow is blocked. The design of the valve ensures reliable sealing and effective operation even under very low temperatures.

Advantages:

1)Superb Flow Control: Offers accurate control of cryogenic fluids with efficiency and safety.

2)Leak-Free Operation: Maintains tight closure and avoids leakage even in extreme temperatures.

3)Durability: Designed to last longer, minimizing the requirement for continuous maintenance.

4)Safety: Offers safe operation, suitable for high-risk cryogenic processes.

Industries:

1)LNG

2)Oil and gas

3)Chemical processing

4)Aerospace

5)Chemical and Petrochemical Industry

6)Biomedical Industry

7)Energy Industry