- Control Valve

- Pneumatic Control Valve

- Pneumatic Angle Control Valve

- 3 Way pneumatic Diaphragm Control Valve

- 3 Way Converging and Diverging Control Valve

- Fluorine Lined Single Seat Control Valve

- Pneumatic Cage Control Valve

- Pneumatic Double Seat Control Valve

- Pneumatic Single Seat Globe Control Valve

- Pneumatic Flow Control Valve

- Pneumatic Sleeve Type Control Valve

- Pneumatic Actuated Globe Type Control Valve

- Electric Actuated Control Valve

- Pneumatic Control Valve

- Cryogenic Valve

- Pressure Reducing Valve

- Safety Valve

- Check Valve

- Gate Valve

- Butterfly Valve

- Globe Valve

- Ball Valve

- Electric Actuated Valve

- Electric Actuated Ball Valve

- Electric Actuated Butterfly Valve

- Electric Actuated Gate Valve

- Electric Actuated Globe Valve

- Pneumatic Actuated Valve

- Plunger Valve

- Strainers

- Steam Trap

- Knife Gate Valve

- Speciality Valve

- Alloy 20 Valve

- Duplex Valve

- Super Duplex Valve

- Hastelloy C276/B3 Valve

- Aluminium Bronze Valve

- Titanium Valve

- Bronze Valve

- Monel Valve

- Triple Duty Valve

- Suction Diffuser

- Diaphragm Valve

- Plug Valve

- Foot Valve

- Air Release Valve

- Surge Anticipator Valve

- Needle Valve

- Balancing Valve

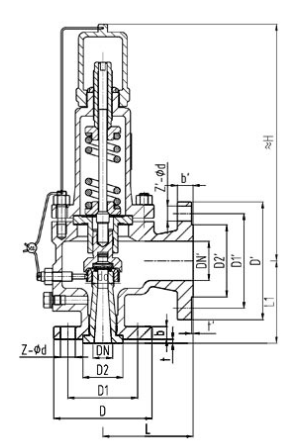

MiddleEast Valve is the best Conventional safety valve supplier in Iran. The valve’s main purpose is to relieve extra pressure by opening when the system’s internal pressure rises above a predefined setpoint. This guarantees that the system operates within safe parameters and avoids potentially catastrophic breakdowns brought on by an excessive buildup of pressure. When the pressure rises above the setpoint, the pressured fluid’s force overrides the spring tension, opening the valve and letting the extra pressure escape to the atmosphere or a suitable relief system.

Under normal operating conditions, the valve is often constructed with a spring-loaded mechanism or a weighted lever system. When the pressure exceeds the set point of the valve, the internal pressure’s force overrides the spring’s or weight’s opposing force, forcing the valve to lift and release the extra pressure into the atmosphere. This quick pressure release contributes to system integrity maintenance and potential risk avoidance.

Advantages:

Reliable Pressure Relief

Cost-Effective

Ease of Maintenance

Longevity

Applications:

Boilers

Pressure Vessels

Steam Systems

Storage Tanks

Power Generation

Chemical Plants

Description:

Body Material – Cast Iron and Cast Steel (A216 WCB, WCC, LCB, LCC, WC6, WC9), Ductile Iron, Stainless Steel (SS316, SS304, SS316L, SS904L, CF8, CF8M, F304, F316, F31L, F51, F3, F55, F91), steel.

Class – 150 – 2500, PN 10 – PN 450

Size – ½” – 40’’

Ends– Butt weld, Socket weld, Flanged, Threaded