- Control Valve

- Pneumatic Control Valve

- Pneumatic Angle Control Valve

- 3 Way pneumatic Diaphragm Control Valve

- 3 Way Converging and Diverging Control Valve

- Fluorine Lined Single Seat Control Valve

- Pneumatic Cage Control Valve

- Pneumatic Double Seat Control Valve

- Pneumatic Single Seat Globe Control Valve

- Pneumatic Flow Control Valve

- Pneumatic Sleeve Type Control Valve

- Pneumatic Actuated Globe Type Control Valve

- Electric Actuated Control Valve

- Pneumatic Control Valve

- Cryogenic Valve

- Pressure Reducing Valve

- Safety Valve

- Check Valve

- Gate Valve

- Butterfly Valve

- Globe Valve

- Ball Valve

- Electric Actuated Valve

- Electric Actuated Ball Valve

- Electric Actuated Butterfly Valve

- Electric Actuated Gate Valve

- Electric Actuated Globe Valve

- Pneumatic Actuated Valve

- Plunger Valve

- Strainers

- Steam Trap

- Knife Gate Valve

- Speciality Valve

- Alloy 20 Valve

- Duplex Valve

- Super Duplex Valve

- Hastelloy C276/B3 Valve

- Aluminium Bronze Valve

- Titanium Valve

- Bronze Valve

- Monel Valve

- Triple Duty Valve

- Suction Diffuser

- Diaphragm Valve

- Plug Valve

- Foot Valve

- Air Release Valve

- Surge Anticipator Valve

- Needle Valve

- Balancing Valve

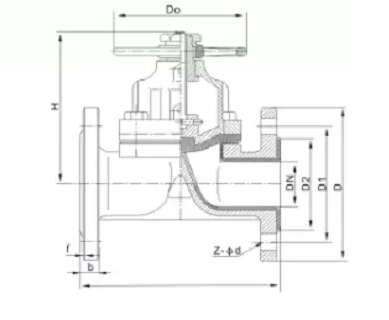

Middleeast valve is the largest Cast Iron Diaphragm Valve Manufacturer in UAE. It is is a type of valve used to control the flow of fluids in a pipeline. It features a flexible diaphragm that acts as a closing mechanism, which can be moved to open, close, or throttle the flow. The valve body is made from cast iron, providing it with strength, durability, and resistance to corrosion, making it suitable for various industrial applications.

How Does a Cast Iron Diaphragm Valve Work?

The working of a cast iron diaphragm valve is relatively simple yet effective. It consists of a valve body, a flexible diaphragm, and a compressor (actuator or handwheel). The diaphragm is attached to a compressor, which, when operated, either lifts or presses the diaphragm against a seat in the valve body.

Open Position: When the compressor is lifted, the diaphragm is raised, allowing fluid to pass through the valve.

Closed Position: When the compressor is lowered, the diaphragm is pressed against the valve seat, stopping the flow of fluid. This design provides a tight seal, even with abrasive or corrosive fluids, by isolating the fluid from the valve’s moving parts.

Functions of a Cast Iron Diaphragm Valve

1)Flow Control: The primary function of the cast iron diaphragm valve is to control the flow of fluids. It can be used to start, stop, or throttle the flow.

2)Isolation: The valve can isolate specific sections of a pipeline, preventing fluid movement in certain areas.

3)Pressure Control: It can be used to regulate the pressure within a system by adjusting the flow rate.

4)Corrosion and Abrasion Resistance: The diaphragm isolates the valve’s internal components from the fluid, protecting them from corrosive or abrasive substances.

Key Features of Cast Iron Diaphragm Valve

1)Simple Operation: Easy to operate, with either manual or automatic actuators.

2)Ease of Installation: Can be easily integrated into existing pipeline systems.

3)Benefits of Using Cast Iron Diaphragm Valves

4)Long Lifespan: The valve’s resistance to corrosion and wear ensures a longer operational life.

5)Energy Efficiency: The smooth operation of the valve can help in maintaining energy efficiency by reducing pressure drops in the system.

Cast Iron Diaphragm Valve Manufacturer in UAE is a reliable and efficient solution for controlling fluid flow in industrial pipelines. Its robust construction, combined with its sealing capabilities and versatility, makes it a preferred choice in many applications.