- Control Valve

- Pneumatic Control Valve

- Pneumatic Angle Control Valve

- 3 Way pneumatic Diaphragm Control Valve

- 3 Way Converging and Diverging Control Valve

- Fluorine Lined Single Seat Control Valve

- Pneumatic Cage Control Valve

- Pneumatic Double Seat Control Valve

- Pneumatic Single Seat Globe Control Valve

- Pneumatic Flow Control Valve

- Pneumatic Sleeve Type Control Valve

- Pneumatic Actuated Globe Type Control Valve

- Electric Actuated Control Valve

- Pneumatic Control Valve

- Cryogenic Valve

- Pressure Reducing Valve

- Safety Valve

- Check Valve

- Gate Valve

- Butterfly Valve

- Globe Valve

- Ball Valve

- Electric Actuated Valve

- Electric Actuated Ball Valve

- Electric Actuated Butterfly Valve

- Electric Actuated Gate Valve

- Electric Actuated Globe Valve

- Pneumatic Actuated Valve

- Plunger Valve

- Strainers

- Steam Trap

- Knife Gate Valve

- Speciality Valve

- Alloy 20 Valve

- Duplex Valve

- Super Duplex Valve

- Hastelloy C276/B3 Valve

- Aluminium Bronze Valve

- Titanium Valve

- Bronze Valve

- Monel Valve

- Triple Duty Valve

- Suction Diffuser

- Diaphragm Valve

- Plug Valve

- Foot Valve

- Air Release Valve

- Surge Anticipator Valve

- Needle Valve

- Balancing Valve

Middleeast valve is the foremost Cast Iron and Cast Steel Ball Valve Manufacturer in UAE. It is types of valves commonly used in various industrial applications to control the flow of fluids. They consist of a spherical disc, known as a ball, that controls the flow through the valve by rotating within the valve body. The primary difference between the two is the material used in their construction—cast iron for cast iron ball valves and cast steel for cast steel ball valves. These materials give the valves specific properties that make them suitable for different applications and environments.

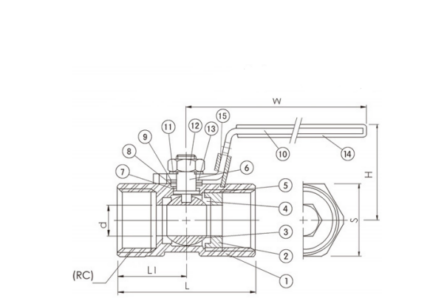

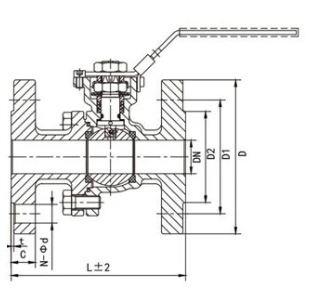

The operation of cast iron and cast steel ball valves is relatively straightforward. The ball inside the valve has a hole through its center, which aligns with the flow of the fluid when the valve is open, allowing the fluid to pass through. When the ball is rotated 90 degrees by turning the valve handle, the hole becomes perpendicular to the flow, effectively stopping the flow. This simple mechanism allows for quick and easy control of fluid flow, making ball valves a popular choice in many systems.

The primary function of cast iron and cast steel ball valves is to control the flow of fluids—such as water, oil, gas, and chemicals—within a piping system. They can be used to start, stop, or regulate flow, offering tight sealing and minimal leakage. Depending on the application, these valves can be manually operated or actuated automatically.

Material Durability:

1)Cast Iron Ball Valves: Known for their excellent compressive strength and resistance to wear and corrosion, making them ideal for non-corrosive media and lower-pressure applications.

2)Cast Steel Ball Valves: Known for their higher tensile strength and toughness, making them suitable for high-pressure and high-temperature applications.

Features:

1)Tight Sealing: Both cast iron and cast steel ball valves offer excellent sealing capabilities, reducing the risk of leaks and ensuring efficient fluid control.

2)Full Bore Design: This design allows for minimal pressure drop and smooth fluid flow, making the system more energy-efficient.

3)Ease of Operation: Simple mechanism requiring minimal effort to open or close the valve, reducing operational strain.

Benefits:

1)Strength and Durability: Cast steel ball valves offer superior strength, making them suitable for demanding environments where high pressure and temperature are factors.

2)Energy Efficiency: The full bore design in both valves ensures that there is little to no pressure drop, leading to energy savings.

3)Easy to Install and Operate: Their straightforward design allows for easy installation and operation, reducing downtime during maintenance or replacement.

These features and benefits make cast iron and cast steel ball valves an essential component in various industrial applications, offering reliable and efficient fluid control.