- Control Valve

- Pneumatic Control Valve

- Pneumatic Angle Control Valve

- 3 Way pneumatic Diaphragm Control Valve

- 3 Way Converging and Diverging Control Valve

- Fluorine Lined Single Seat Control Valve

- Pneumatic Cage Control Valve

- Pneumatic Double Seat Control Valve

- Pneumatic Single Seat Globe Control Valve

- Pneumatic Flow Control Valve

- Pneumatic Sleeve Type Control Valve

- Pneumatic Actuated Globe Type Control Valve

- Electric Actuated Control Valve

- Pneumatic Control Valve

- Cryogenic Valve

- Pressure Reducing Valve

- Safety Valve

- Check Valve

- Gate Valve

- Butterfly Valve

- Globe Valve

- Ball Valve

- Electric Actuated Valve

- Electric Actuated Ball Valve

- Electric Actuated Butterfly Valve

- Electric Actuated Gate Valve

- Electric Actuated Globe Valve

- Pneumatic Actuated Valve

- Plunger Valve

- Strainers

- Steam Trap

- Knife Gate Valve

- Speciality Valve

- Alloy 20 Valve

- Duplex Valve

- Super Duplex Valve

- Hastelloy C276/B3 Valve

- Aluminium Bronze Valve

- Titanium Valve

- Bronze Valve

- Monel Valve

- Triple Duty Valve

- Suction Diffuser Valve

- Diaphragm Valve

- Plug Valve

- Foot Valve

- Air Release Valve

- Surge Anticipator Valve

- Needle Valve

- Balancing Valve

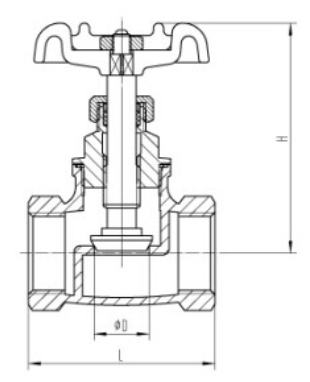

A bronze globe valve is a type of valve used to regulate the flow of liquid or gas in a pipeline. Made from bronze, which is an alloy of copper and tin, these valves are known for their excellent corrosion resistance and durability. Globe valves, in general, are named for their spherical body shape and are commonly used in applications where precise flow control is necessary. Bronze globe valves are specifically favoured in industries such as marine, oil and gas, and HVAC systems due to their ability to withstand harsh environments.

How Does a Bronze Globe Valve Work?

Bronze globe valves work by moving a disc (the plug) that opens, closes, or partially obstructs the flow of fluid through the valve. The design of a globe valve typically includes a movable plug or disc element and a stationary ring seat in a generally spherical body. Here’s a step-by-step breakdown of how it operates:

1)Opening and Closing: The valve is operated by a handwheel or an actuator, which raises or lowers the stem connected to the disc. When the handwheel is turned counterclockwise, the disc is lifted off the seat, allowing fluid to pass through the valve. Turning the handwheel clockwise lowers the disc back onto the seat, stopping the flow.

2)Flow Regulation: Unlike other valves, the globe valve’s design allows for fine control over the flow rate. The disc can be positioned at various points between fully open and fully closed, enabling precise adjustment of the flow rate.

3)Directional Flow: Globe valves are usually installed in a way that ensures the fluid flow is under the seat. This setup provides better sealing when the valve is closed, reducing the risk of leakage.

Key Features of Bronze Globe Valves:

1)Material Durability: Made from bronze, these valves exhibit excellent resistance to corrosion and wear, making them ideal for use in environments where exposure to seawater or other corrosive fluids is common.

2)Precise Flow Control: The design of the globe valve allows for accurate control over fluid flow, making it suitable for applications requiring fine-tuned flow regulation.

3)Excellent Sealing Capabilities: The disc and seat design of a bronze globe valve provide a tight seal, reducing the risk of leakage even under high-pressure conditions.

4)Temperature Resistance: Bronze is capable of withstanding a wide range of temperatures, making these valves suitable for both hot and cold fluid applications.

5)Ease of Maintenance: Due to their simple design, bronze globe valves are relatively easy to maintain and repair. The disc and seat can be easily accessed, cleaned, or replaced if needed.

Bronze globe valves are used in various industries and applications, such as:

1)Marine Applications: Ideal for seawater systems due to their corrosion-resistant properties.

2)Oil and Gas: Used for controlling the flow of fluids in pipelines.

3)HVAC Systems: Suitable for regulating the flow of steam or chilled water.