- Control Valve

- Pneumatic Control Valve

- Pneumatic Angle Control Valve

- 3 Way pneumatic Diaphragm Control Valve

- 3 Way Converging and Diverging Control Valve

- Fluorine Lined Single Seat Control Valve

- Pneumatic Cage Control Valve

- Pneumatic Double Seat Control Valve

- Pneumatic Single Seat Globe Control Valve

- Pneumatic Flow Control Valve

- Pneumatic Sleeve Type Control Valve

- Pneumatic Actuated Globe Type Control Valve

- Electric Actuated Control Valve

- Pneumatic Control Valve

- Cryogenic Valve

- Pressure Reducing Valve

- Safety Valve

- Check Valve

- Gate Valve

- Butterfly Valve

- Globe Valve

- Ball Valve

- Electric Actuated Valve

- Electric Actuated Ball Valve

- Electric Actuated Butterfly Valve

- Electric Actuated Gate Valve

- Electric Actuated Globe Valve

- Pneumatic Actuated Valve

- Plunger Valve

- Strainers

- Steam Trap

- Knife Gate Valve

- Speciality Valve

- Alloy 20 Valve

- Duplex Valve

- Super Duplex Valve

- Hastelloy C276/B3 Valve

- Aluminium Bronze Valve

- Titanium Valve

- Bronze Valve

- Monel Valve

- Triple Duty Valve

- Suction Diffuser

- Diaphragm Valve

- Plug Valve

- Foot Valve

- Air Release Valve

- Surge Anticipator Valve

- Needle Valve

- Balancing Valve

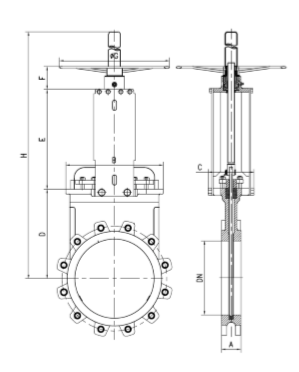

Middleeast valve is the leading Bidirectional knife gate valve supplier in Saudi Arabia. A Bidirectional Knife Gate Valve is a type of industrial valve designed to handle thick fluids, slurries, or solids in piping systems. It is called “bidirectional” because it can control the flow of media in both directions, making it highly versatile in various industrial applications.

Working: the knife gate valve operates by lowering or raising a sharp-edged gate (knife) to cut through media and either block or allow the flow. When the valve is open, the gate is lifted out of the flow path. When closed, the gate cuts through any solidifying media and seals the pipe in both directions, ensuring no leaks or backflow. The bidirectional design means the valve doesn’t depend on the flow direction for sealing, making it ideal for reverse flow scenarios.

Function:

1)Flow Control: It regulates or stops the flow of media, especially where there are large particles or viscous materials.

2)Handling Slurries: The valve excels in handling abrasive slurries, dense liquids, and high-viscosity fluids that other valves struggle with.

3)Bidirectional Sealing: The ability to provide tight sealing in both directions ensures there is no leakage or contamination from backflow.

Features:

1)Sharp-Edged Gate: Designed to cut through solid or semi-solid materials within the media, preventing clogging.

2)Resilient Sealing: Equipped with soft or metal seats that offer tight sealing in both directions of the flow.

3)Compact Design: These valves typically have a compact body, minimizing space requirements in piping systems.

4)Non-clogging: Due to the knife-like gate, it effectively reduces the chances of clogging from solid materials.

5)Corrosion and Wear Resistance: The body material is often made of durable metals to resist abrasion from harsh media.

Bidirectional knife gate valves are widely used in industries such as mining, wastewater, chemical, and pulp and paper due to their reliability in handling difficult media and providing tight shut-off in challenging environments.

Description:

Body material: Carbon Steel, Ductile Iron, SS316,

Nominal Size: DN50 to DN400

Nominal Pressure: Class150 to Class30, PN10

End Type: Wafer Type, Lug Type

Operation: Handwheel, Electric Actuated, Pneumatic Actuated