- Control Valve

- Pneumatic Control Valve

- Pneumatic Angle Control Valve

- 3 Way pneumatic Diaphragm Control Valve

- 3 Way Converging and Diverging Control Valve

- Fluorine Lined Single Seat Control Valve

- Pneumatic Cage Control Valve

- Pneumatic Double Seat Control Valve

- Pneumatic Single Seat Globe Control Valve

- Pneumatic Flow Control Valve

- Pneumatic Sleeve Type Control Valve

- Pneumatic Actuated Globe Type Control Valve

- Electric Actuated Control Valve

- Pneumatic Control Valve

- Cryogenic Valve

- Pressure Reducing Valve

- Safety Valve

- Check Valve

- Gate Valve

- Butterfly Valve

- Globe Valve

- Ball Valve

- Electric Actuated Valve

- Electric Actuated Ball Valve

- Electric Actuated Butterfly Valve

- Electric Actuated Gate Valve

- Electric Actuated Globe Valve

- Pneumatic Actuated Valve

- Plunger Valve

- Strainers

- Steam Trap

- Knife Gate Valve

- Speciality Valve

- Alloy 20 Valve

- Duplex Valve

- Super Duplex Valve

- Hastelloy C276/B3 Valve

- Aluminium Bronze Valve

- Titanium Valve

- Bronze Valve

- Monel Valve

- Triple Duty Valve

- Suction Diffuser

- Diaphragm Valve

- Plug Valve

- Foot Valve

- Air Release Valve

- Surge Anticipator Valve

- Needle Valve

- Balancing Valve

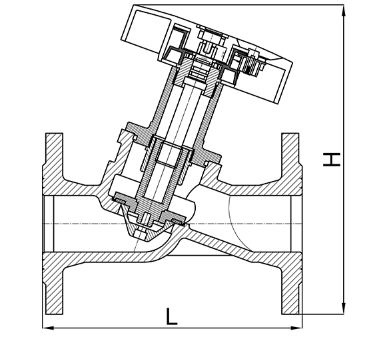

Balancing Valve Suppliers in Saudi Arabia: Ensuring Optimal Flow Distribution Across Systems

Middleeast valve is a well known Balancing valve suppliers in Saudi Arabia. It is designed to balance the flow of fluid within a piping system, ensuring that each branch or circuit receives the intended flow rate. It helps in preventing uneven distribution of fluid, which can lead to issues such as inadequate heating or cooling in certain areas of an HVAC system or inconsistent water pressure in plumbing systems.

Main Components of a Balancing Valve:

1)Valve Body – The central housing that contains all the internal parts.

2)Flow Control Mechanism – A mechanism employed to control and regulate the flow in the system.

3)Handwheel or Actuator – Employed for controlling or adjusting the valve manually to get the required flow.

4)Pressure Ports – Ports employed to monitor and regulate the pressure for accurate balancing.

Working Mechanism:

Balancing valve work by adjusting flow within system to ensure each branch or loop receive correct amount of fluid. The valve is calibrated based on desired flow rate, and it automatically adjust to maintain system balance. This ensure that the system operate at peak efficiency, preventing issue like uneven heating or cooling, and reducing energy consumption.

Advantages of Using Balancing Valve:

Optimized Flow Distribution: Provides the right flow to every component of the system.

Increased System Efficiency: Reduces energy usage by avoiding imbalances.

Increased Comfort: Provides uniform temperature distribution in HVAC and district heating systems.

Less Wear and Tear: Avoids system stress, extending equipment life.

Description:

Available Material: Ductile iron, Cast iron, WCB, SS304, SS316, Bronze, SS410, SS431

Size: 2 Inch-24 Inch

Class: 150-300

Nominal Pressure: PN10-PN40

Ends: Flanged

Operations: Hand wheel operated.