- Control Valve

- Pneumatic Control Valve

- Pneumatic Angle Control Valve

- 3 Way pneumatic Diaphragm Control Valve

- 3 Way Converging and Diverging Control Valve

- Fluorine Lined Single Seat Control Valve

- Pneumatic Cage Control Valve

- Pneumatic Double Seat Control Valve

- Pneumatic Single Seat Globe Control Valve

- Pneumatic Flow Control Valve

- Pneumatic Sleeve Type Control Valve

- Pneumatic Actuated Globe Type Control Valve

- Electric Actuated Control Valve

- Pneumatic Control Valve

- Cryogenic Valve

- Pressure Reducing Valve

- Safety Valve

- Check Valve

- Gate Valve

- Butterfly Valve

- Globe Valve

- Ball Valve

- Electric Actuated Valve

- Electric Actuated Ball Valve

- Electric Actuated Butterfly Valve

- Electric Actuated Gate Valve

- Electric Actuated Globe Valve

- Pneumatic Actuated Valve

- Plunger Valve

- Strainers

- Steam Trap

- Knife Gate Valve

- Speciality Valve

- Alloy 20 Valve

- Duplex Valve

- Super Duplex Valve

- Hastelloy C276/B3 Valve

- Aluminium Bronze Valve

- Titanium Valve

- Bronze Valve

- Monel Valve

- Triple Duty Valve

- Suction Diffuser

- Diaphragm Valve

- Plug Valve

- Foot Valve

- Air Release Valve

- Surge Anticipator Valve

- Needle Valve

- Balancing Valve

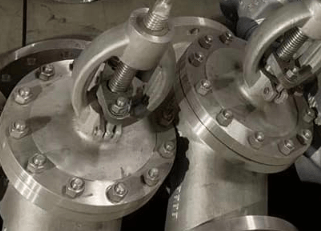

An Alloy Globe Valve is a type of valve made from various alloy materials, typically chosen for their enhanced strength, corrosion resistance, and durability in high-temperature or high-pressure environments. These valves are primarily used in industries where standard materials, like carbon steel or cast iron, may degrade quickly. The use of alloys such as stainless steel, bronze, or Inconel allows the globe valve to operate efficiently in harsh conditions.

Function of Alloy Globe Valve

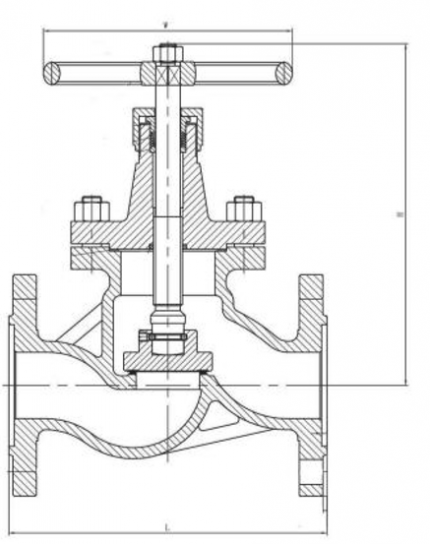

The primary function of an alloy globe valve is to regulate the flow of liquids, gases, or steam within a pipeline. Unlike ball or gate valves, globe valves are designed for precise flow control. They are ideal for applications where throttling or frequent adjustments are needed. Their design ensures minimal leakage when fully closed and allows for variable flow control when partially open.

The working mechanism of an alloy globe valve revolves around a movable disk and a stationary ring seat in a generally spherical-shaped body, hence the name “globe” valve. Here’s how it functions:

1)Open Position: When the handwheel is rotated, the disk is lifted from the seat, allowing the fluid to pass through.

2)Throttling: By partially opening or closing the valve, the flow can be throttled for precise control.

3)Closed Position: When fully closed, the disk sits tightly on the seat, halting the flow completely.

The flow in globe valves is usually linear and controlled by the perpendicular movement of the disk.

Features of Alloy Globe Valve:

1)Corrosion Resistance: The use of alloys enhances the valve’s ability to resist corrosion, making it suitable for chemical processing and seawater applications.

2)High-Temperature Tolerance: Alloy materials like Inconel or stainless steel enable the valve to withstand extreme temperatures, both hot and cold.

3)Flow Control: Globe valves provide superior throttling capabilities, ideal for applications where flow regulation is necessary.

4)Tight Sealing: Due to their design, alloy globe valves can create a tight seal when fully closed, minimizing leakage.

This combination of enhanced material properties and precise flow control makes alloy globe valves a versatile choice across industries like oil and gas, chemical processing, and power generation.